It has been another busy week at Preston for working members of the Furness Railway Trust.

Wednesday was tidy up day after the shed had been opened to the public during the Ribble Steam Railway’s Autumn Steam Gala. The unsold second-hand books now fit on the bookshelves in the mess room and so the table is clear of boxes! The opportunity was also taken to clear out some sales items that were long past their shelf life.

The recent better weather has allowed progress outside the shed on Great Western Railway 0-6-2T No. 5643’s side tanks, bunker and cab roof. Inside the shed, Keith has started to reassemble 5643’s radial truck and, with the new axle pads for the driving wheels received, it should now be possible to lower the frames. Having completed the reaming out of the remaining first batch of stay holes in the firebox the previous Thursday, attention was now turned to completing the riveting work elsewhere on the loco on Friday.

The recent better weather has allowed progress outside the shed on Great Western Railway 0-6-2T No. 5643’s side tanks, bunker and cab roof. Inside the shed, Keith has started to reassemble 5643’s radial truck and, with the new axle pads for the driving wheels received, it should now be possible to lower the frames. Having completed the reaming out of the remaining first batch of stay holes in the firebox the previous Thursday, attention was now turned to completing the riveting work elsewhere on the loco on Friday.

Meanwhile, last Wednesday saw final preparations for the departure of Furness Railway 0-4-0 No. 20, which left Preston by low loader to go to the East Lancashire Railway (ELR) for its forthcoming gala appearance after lunch the following day. John Dixon and Sam were at Bury in order to re-fit the guard irons and sand pipes, fill the tender tank and to light a warming fire.

Meanwhile, last Wednesday saw final preparations for the departure of Furness Railway 0-4-0 No. 20, which left Preston by low loader to go to the East Lancashire Railway (ELR) for its forthcoming gala appearance after lunch the following day. John Dixon and Sam were at Bury in order to re-fit the guard irons and sand pipes, fill the tender tank and to light a warming fire.

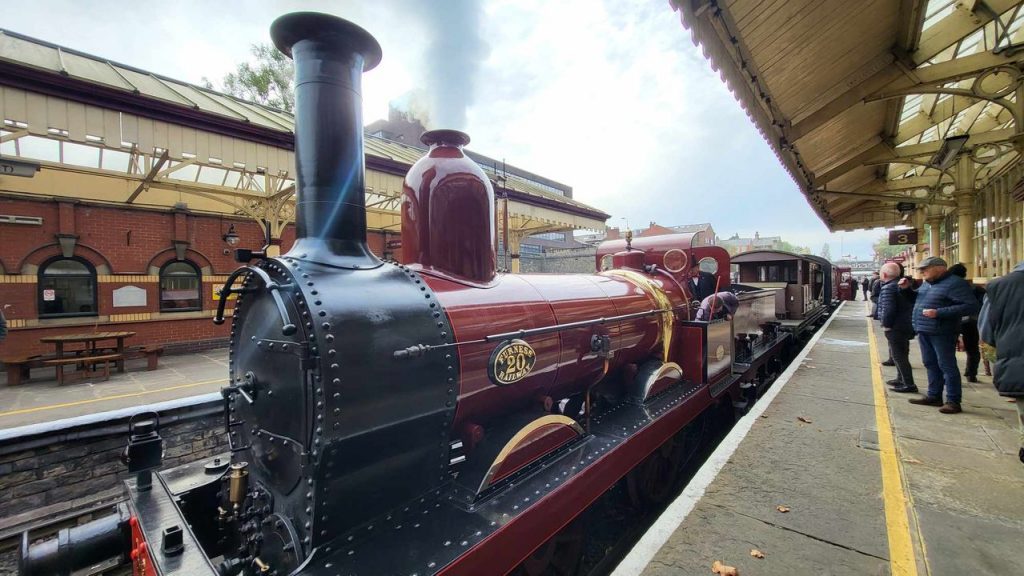

The ELR had asked for an early test run to Ramsbotton to be undertaken to check that FR 20 could cope with the proposed load (two Mark 1 carriages) and to assess the time required to make the journey. So Sam picked up Tim at Horwich Parkway station on Friday morning and the loco was lit up around 08.30. It was certainly the centre of attention in the loco yard as it was cleaned (again!) and prepared for the test run. Andy Booth and Liam Barnes were assigned the duties of driver and fireman, with Sam and Tim also on board to assist with proceedings.

The run had not been advertised and was even a surprise to the signalman at Bury when the engine appeared. However, two Mark 1 coaches were duly collected and moved to platform 4 at Bury Bolton Street station, where tea was duly taken by all concerned. Andy Booth’s Hunslet 0-6-0 tender loco Douglas was also in the station with the five coach dining train, which left at 12.30.

The run had not been advertised and was even a surprise to the signalman at Bury when the engine appeared. However, two Mark 1 coaches were duly collected and moved to platform 4 at Bury Bolton Street station, where tea was duly taken by all concerned. Andy Booth’s Hunslet 0-6-0 tender loco Douglas was also in the station with the five coach dining train, which left at 12.30.

It had been decided to stop at all stations on the way to Ramsbottom to ensure that there would be no problems in re-starting the train on the gradient, and the opportunity was taken to photograph the train in Summerseat station.

It had been decided to stop at all stations on the way to Ramsbottom to ensure that there would be no problems in re-starting the train on the gradient, and the opportunity was taken to photograph the train in Summerseat station.

Ramsbottom was duly reached in a time of 25 minutes without breaking sweat, so it was time for another cup of tea (what, more tea? Ed.) and a chat with Responsible Officer for the day, Richard Law. Once the dining train had passed through Ramsbottom on its way back towards Bury, it was time to complete the return trip, this time non-stop. It was decided on return that there was no need for a second test run and so the carriages were deposited back into the siding and FR 20 returned to the shed. All in all, a very satisfactory day.

Ramsbottom was duly reached in a time of 25 minutes without breaking sweat, so it was time for another cup of tea (what, more tea? Ed.) and a chat with Responsible Officer for the day, Richard Law. Once the dining train had passed through Ramsbottom on its way back towards Bury, it was time to complete the return trip, this time non-stop. It was decided on return that there was no need for a second test run and so the carriages were deposited back into the siding and FR 20 returned to the shed. All in all, a very satisfactory day.

Finally, a date for your diary. Phil Probert informs us that there will be a talk on the new build LNER G5 locomotive at Ghyll View Farm, Gill Lane, Longton, Preston PR4 4ST at 07.30 pm on Thursday, 10th October. All welcome.

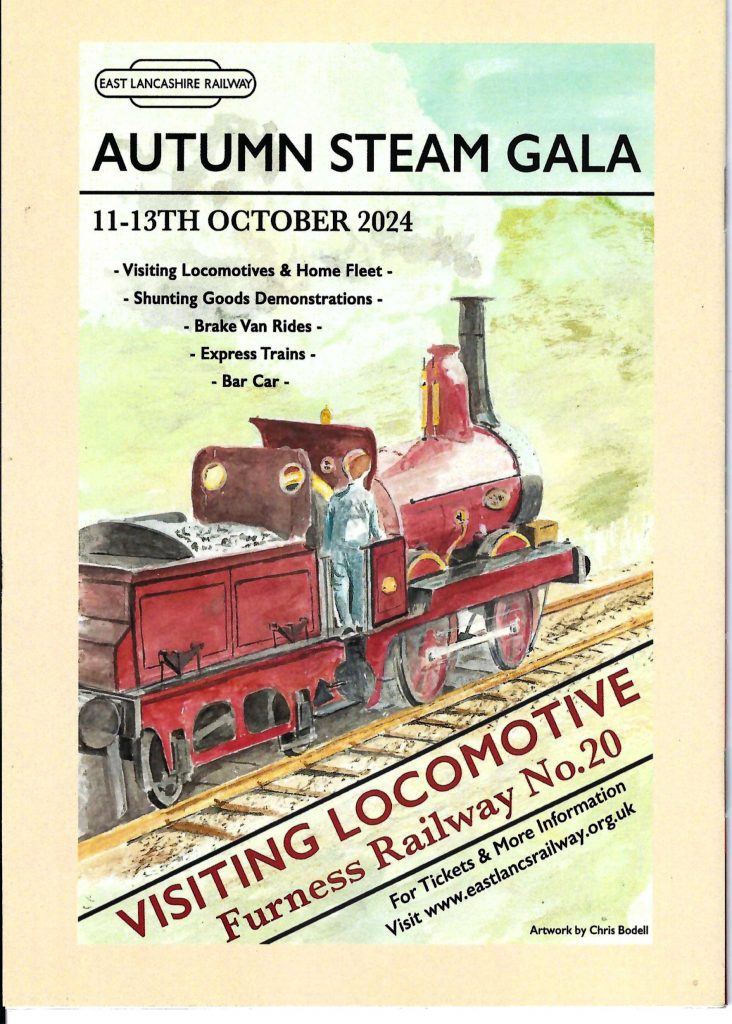

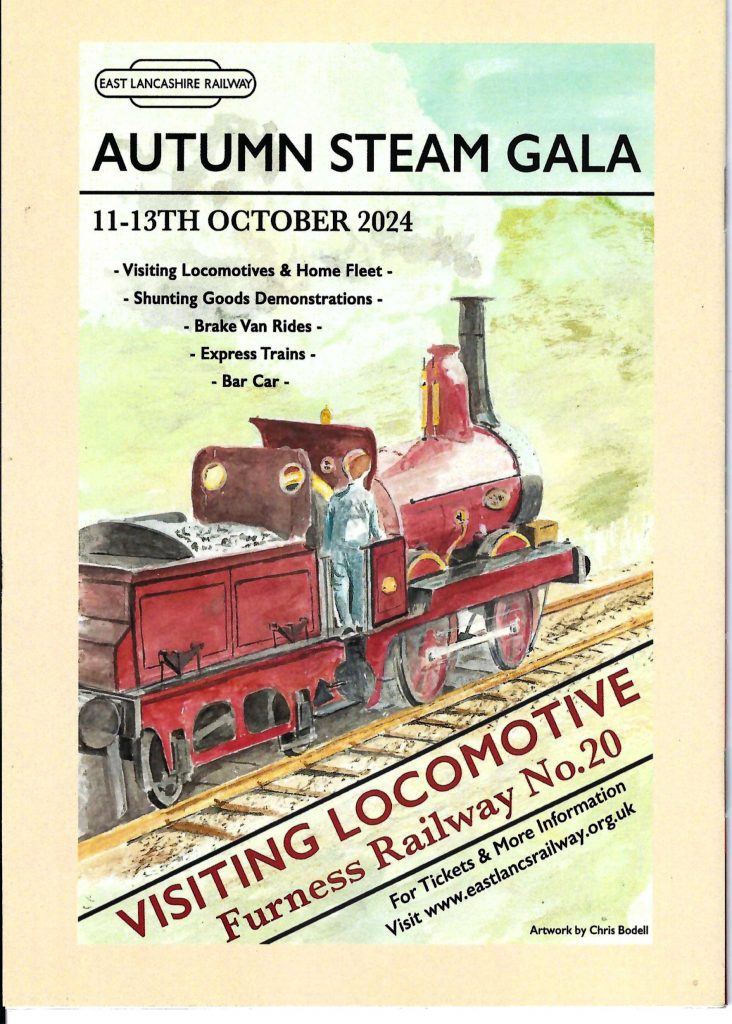

We leave you this week with another reminder of the forthcoming Autumn Steam Gala at the East Lancashire Railway this next weekend:

The recent better weather conditions (OK, forget today!) have enabled good progress to be made outside the shed on the refurbishment of Great Western Railway 0-6-2T No. 5643’s bunker, which John Dixon has been persevering with, seen here removing rust.

The recent better weather conditions (OK, forget today!) have enabled good progress to be made outside the shed on the refurbishment of Great Western Railway 0-6-2T No. 5643’s bunker, which John Dixon has been persevering with, seen here removing rust. Jon and Sim have been busy applying green undercoat to the cab roof.

Jon and Sim have been busy applying green undercoat to the cab roof. Ed has been taking his turn grinding off stay heads on 5643’s firebox in preparation for the stays to be replaced.

Ed has been taking his turn grinding off stay heads on 5643’s firebox in preparation for the stays to be replaced. This last weekend has seen what was scheduled to be the last major event for the Furness Railway Trust this year, with Furness Railway No. 20 booked to appear at the East Lancashire Railway’s Autumn Steam Gala on the 11th, 12th and 13th October. As with all these occasions, there needs to be some advance preparation and Phil Burton, Alison, Ade and Anne were busy in the mess room last Wednesday sorting out sales stock and, incidentally, taking the opportunity to get rid of some long out-dated items that were taking up unnecessary room.

This last weekend has seen what was scheduled to be the last major event for the Furness Railway Trust this year, with Furness Railway No. 20 booked to appear at the East Lancashire Railway’s Autumn Steam Gala on the 11th, 12th and 13th October. As with all these occasions, there needs to be some advance preparation and Phil Burton, Alison, Ade and Anne were busy in the mess room last Wednesday sorting out sales stock and, incidentally, taking the opportunity to get rid of some long out-dated items that were taking up unnecessary room. Ian Massey was with us once again on Wednesday, seen here working on Great Western Railway ‘Hall’ 4-6-0 No. 4979 Wootton Hall’s tender where more new plate has been welded in.

Ian Massey was with us once again on Wednesday, seen here working on Great Western Railway ‘Hall’ 4-6-0 No. 4979 Wootton Hall’s tender where more new plate has been welded in. Outside, Sim and Jon were applying some red oxide to GWR 0-6-2T No. 5643’s cab roof.

Outside, Sim and Jon were applying some red oxide to GWR 0-6-2T No. 5643’s cab roof.

New axle pad oilers have arrived for 5643’s driving wheels this week.

New axle pad oilers have arrived for 5643’s driving wheels this week. And so to Bury where Alison is seen with the FRT’s sales stand, which she looked after on Friday and Saturday. Phil and Anne appeared on Sunday to continue with the sales to the many visitors to the Gala.

And so to Bury where Alison is seen with the FRT’s sales stand, which she looked after on Friday and Saturday. Phil and Anne appeared on Sunday to continue with the sales to the many visitors to the Gala. FR 20 worked either on two Mark 1 carriage shuttles to Ramsbottom, seen here with former RSR resident L&Y ‘Pug’ No. 19…

FR 20 worked either on two Mark 1 carriage shuttles to Ramsbottom, seen here with former RSR resident L&Y ‘Pug’ No. 19… … or operating brake van rides top and tailed with recent Ribble Steam Railway resident Barclay 0-4-0ST No. 1969 JN Derbyshire.

… or operating brake van rides top and tailed with recent Ribble Steam Railway resident Barclay 0-4-0ST No. 1969 JN Derbyshire. Seen again, at Bury Bolton Street station. Photo kindly shared by John Earnshaw Photography, with thanks.

Seen again, at Bury Bolton Street station. Photo kindly shared by John Earnshaw Photography, with thanks. Gremlins struck on Friday afternoon when a noise from FR 20’s right hand side suggested that an examination was required. It was decided to miss the loco’s turn on the evening fish and chip special to Ramsbottom and head back to the shed where removal of the front right hand cylinder cover revealed that a small gap had opened up been the piston and the retaining nut. An 80 thou’ bronze washer was quickly machined up by Bill Beverage and fitted. Matt Hainsworth is seen refitting the cylinder cover on Saturday morning (with Bill looking on) and, after what was the equivalent of a Formula One pit stop, the loco was quickly back in service with the 11.37 brake van trip to Burrs. Our thanks go to Matt, Bill and Andy Booth for their assistance in getting the loco back on the road so quickly.

Gremlins struck on Friday afternoon when a noise from FR 20’s right hand side suggested that an examination was required. It was decided to miss the loco’s turn on the evening fish and chip special to Ramsbottom and head back to the shed where removal of the front right hand cylinder cover revealed that a small gap had opened up been the piston and the retaining nut. An 80 thou’ bronze washer was quickly machined up by Bill Beverage and fitted. Matt Hainsworth is seen refitting the cylinder cover on Saturday morning (with Bill looking on) and, after what was the equivalent of a Formula One pit stop, the loco was quickly back in service with the 11.37 brake van trip to Burrs. Our thanks go to Matt, Bill and Andy Booth for their assistance in getting the loco back on the road so quickly. The ELR had also brought in former Bury resident BR 9F 2-10-0 No. 92134 seen alongside FR 20 at Ramsbottom on Saturday evening.

The ELR had also brought in former Bury resident BR 9F 2-10-0 No. 92134 seen alongside FR 20 at Ramsbottom on Saturday evening. The recent better weather has allowed progress outside the shed on Great Western Railway 0-6-2T No. 5643’s side tanks, bunker and cab roof. Inside the shed, Keith has started to reassemble 5643’s radial truck and, with the new axle pads for the driving wheels received, it should now be possible to lower the frames. Having completed the reaming out of the remaining first batch of stay holes in the firebox the previous Thursday, attention was now turned to completing the riveting work elsewhere on the loco on Friday.

The recent better weather has allowed progress outside the shed on Great Western Railway 0-6-2T No. 5643’s side tanks, bunker and cab roof. Inside the shed, Keith has started to reassemble 5643’s radial truck and, with the new axle pads for the driving wheels received, it should now be possible to lower the frames. Having completed the reaming out of the remaining first batch of stay holes in the firebox the previous Thursday, attention was now turned to completing the riveting work elsewhere on the loco on Friday. Meanwhile, last Wednesday saw final preparations for the departure of Furness Railway 0-4-0 No. 20, which left Preston by low loader to go to the East Lancashire Railway (ELR) for its forthcoming gala appearance after lunch the following day. John Dixon and Sam were at Bury in order to re-fit the guard irons and sand pipes, fill the tender tank and to light a warming fire.

Meanwhile, last Wednesday saw final preparations for the departure of Furness Railway 0-4-0 No. 20, which left Preston by low loader to go to the East Lancashire Railway (ELR) for its forthcoming gala appearance after lunch the following day. John Dixon and Sam were at Bury in order to re-fit the guard irons and sand pipes, fill the tender tank and to light a warming fire. The run had not been advertised and was even a surprise to the signalman at Bury when the engine appeared. However, two Mark 1 coaches were duly collected and moved to platform 4 at Bury Bolton Street station, where tea was duly taken by all concerned. Andy Booth’s Hunslet 0-6-0 tender loco Douglas was also in the station with the five coach dining train, which left at 12.30.

The run had not been advertised and was even a surprise to the signalman at Bury when the engine appeared. However, two Mark 1 coaches were duly collected and moved to platform 4 at Bury Bolton Street station, where tea was duly taken by all concerned. Andy Booth’s Hunslet 0-6-0 tender loco Douglas was also in the station with the five coach dining train, which left at 12.30. It had been decided to stop at all stations on the way to Ramsbottom to ensure that there would be no problems in re-starting the train on the gradient, and the opportunity was taken to photograph the train in Summerseat station.

It had been decided to stop at all stations on the way to Ramsbottom to ensure that there would be no problems in re-starting the train on the gradient, and the opportunity was taken to photograph the train in Summerseat station. Ramsbottom was duly reached in a time of 25 minutes without breaking sweat, so it was time for another cup of tea (what, more tea? Ed.) and a chat with Responsible Officer for the day, Richard Law. Once the dining train had passed through Ramsbottom on its way back towards Bury, it was time to complete the return trip, this time non-stop. It was decided on return that there was no need for a second test run and so the carriages were deposited back into the siding and FR 20 returned to the shed. All in all, a very satisfactory day.

Ramsbottom was duly reached in a time of 25 minutes without breaking sweat, so it was time for another cup of tea (what, more tea? Ed.) and a chat with Responsible Officer for the day, Richard Law. Once the dining train had passed through Ramsbottom on its way back towards Bury, it was time to complete the return trip, this time non-stop. It was decided on return that there was no need for a second test run and so the carriages were deposited back into the siding and FR 20 returned to the shed. All in all, a very satisfactory day.

The Ribble Steam Railway Autumn Steam Gala took place this last Saturday and Sunday, so there was considerable effort made to prepare and clean Furness Railway locomotive No. 20 so that it looked its best for the occasion.

The Ribble Steam Railway Autumn Steam Gala took place this last Saturday and Sunday, so there was considerable effort made to prepare and clean Furness Railway locomotive No. 20 so that it looked its best for the occasion. The Gala saw the first publicised appearances of newly overhauled Borrows 0-4-0 well tank No. 48 of 1906 The King and Andrew Barclay 0-4-0ST No. 1969 of 1929 JN Derbyshire. Both of these locomotives were in ex-works condition and worked back to back for passenger workings, being accorded by some the nickname the ‘Preston Double Fairlie’. With other home-based locos Bagnall 0-6-0ST No. 2680 Courageous and Grant Richie 0-4-0ST No. 272 also in steam, along with the chance to ride in the FRT’s Great Eastern Railway royal saloon No. 5 and partake of tea, coffee, ploughman’s lunch and cream tea, there was plenty to see and do. In fact a number of visitors were noted to have spent both days at the Gala.

The Gala saw the first publicised appearances of newly overhauled Borrows 0-4-0 well tank No. 48 of 1906 The King and Andrew Barclay 0-4-0ST No. 1969 of 1929 JN Derbyshire. Both of these locomotives were in ex-works condition and worked back to back for passenger workings, being accorded by some the nickname the ‘Preston Double Fairlie’. With other home-based locos Bagnall 0-6-0ST No. 2680 Courageous and Grant Richie 0-4-0ST No. 272 also in steam, along with the chance to ride in the FRT’s Great Eastern Railway royal saloon No. 5 and partake of tea, coffee, ploughman’s lunch and cream tea, there was plenty to see and do. In fact a number of visitors were noted to have spent both days at the Gala. There was also a large second-hand book stall in the FRT shed which raised some welcome funds and it was a great opportunity to meet up with friends and visitors and display the current work being undertaken by the Trust.

There was also a large second-hand book stall in the FRT shed which raised some welcome funds and it was a great opportunity to meet up with friends and visitors and display the current work being undertaken by the Trust. Wednesday morning saw Peckett 0-4-0ST Caliban’s boiler being loaded onto a hi-ab lorry…

Wednesday morning saw Peckett 0-4-0ST Caliban’s boiler being loaded onto a hi-ab lorry…  …which swiftly departed to Bradshaw Sheet Metal near Bolton to pick up the smokebox before heading off south to the Williton workshop of West Somerset Restoration which has been contracted to fit a new inner firebox, fit new tubes and conduct a hydraulic test.

…which swiftly departed to Bradshaw Sheet Metal near Bolton to pick up the smokebox before heading off south to the Williton workshop of West Somerset Restoration which has been contracted to fit a new inner firebox, fit new tubes and conduct a hydraulic test. Having despatched the boiler it was then time to fill the large skip that had been delivered, with John, Tim and Ed loading two sets of boiler tubes (5643 and Caliban), two sets of superheater elements (5643 and 4979) and 5643’s flue tubes. Needless to say, the work in the hot sun was interspersed by the odd cup of tea!

Having despatched the boiler it was then time to fill the large skip that had been delivered, with John, Tim and Ed loading two sets of boiler tubes (5643 and Caliban), two sets of superheater elements (5643 and 4979) and 5643’s flue tubes. Needless to say, the work in the hot sun was interspersed by the odd cup of tea! The hi-ab lorry set off from Williton before dawn on Thursday to deliver the tank to Tyseley Locomotive Works and then pick up the new superheater elements for GWR 0-6-2T No. 5643 and the second-hand coupling rod that had been purchased for GWR ‘Hall’ class 4-6-0 No. 4979 Wootton Hall. These were delivered to Preston around 2 pm that day, being received by John Dixon.

The hi-ab lorry set off from Williton before dawn on Thursday to deliver the tank to Tyseley Locomotive Works and then pick up the new superheater elements for GWR 0-6-2T No. 5643 and the second-hand coupling rod that had been purchased for GWR ‘Hall’ class 4-6-0 No. 4979 Wootton Hall. These were delivered to Preston around 2 pm that day, being received by John Dixon. Friday saw John, Keith and Tim assemble to tidy up the shed, stack the superheater elements and bring in the coupling rod.

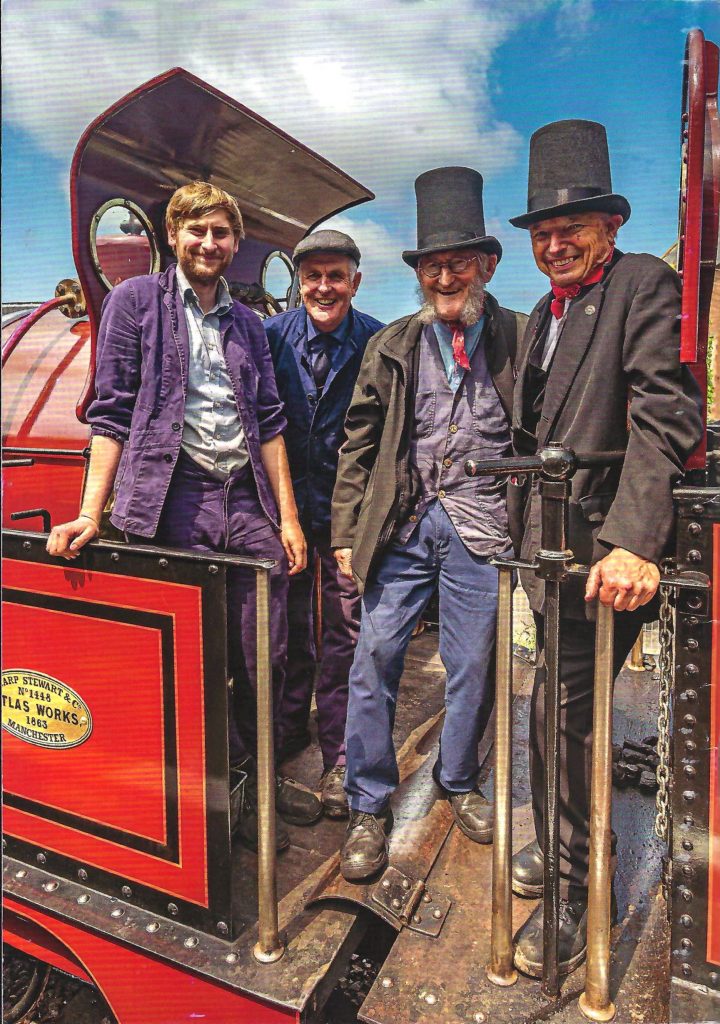

Friday saw John, Keith and Tim assemble to tidy up the shed, stack the superheater elements and bring in the coupling rod. Finally, we received this week the latest West Somerset Railway Journal, which features some recognisable ‘old timers’ on the back cover celebrating the 150th anniversary of the Watchet to Minehead Railway.

Finally, we received this week the latest West Somerset Railway Journal, which features some recognisable ‘old timers’ on the back cover celebrating the 150th anniversary of the Watchet to Minehead Railway. Caliban’s boiler is scheduled to be picked up on Wednesday morning for its trip to the Williton workshop of the West Somerset Railway where it will receive a new inner firebox. Ade has been in today to move 5643’s side tanks out of the way for the booked hi-ab to lift the boiler. Hopefully the hi-ab will also be able to bring back the first batch of stays for 5643 that we have ordered from Williton and then pick up the superheater elements for 5643 and a coupling rod for Wootton Hall from Tyseley. It will also be transferring a GWR locomotive water tank from Williton to Tyseley for someone else, so no mileage wasted here! (Don’t ask how many telephone calls and emails this has taken to organise!)

Caliban’s boiler is scheduled to be picked up on Wednesday morning for its trip to the Williton workshop of the West Somerset Railway where it will receive a new inner firebox. Ade has been in today to move 5643’s side tanks out of the way for the booked hi-ab to lift the boiler. Hopefully the hi-ab will also be able to bring back the first batch of stays for 5643 that we have ordered from Williton and then pick up the superheater elements for 5643 and a coupling rod for Wootton Hall from Tyseley. It will also be transferring a GWR locomotive water tank from Williton to Tyseley for someone else, so no mileage wasted here! (Don’t ask how many telephone calls and emails this has taken to organise!) There has been further work on Great Western Railway 0-6-2T No. 5643. John Dixon is seen busy with the welder with one of 5643’s side tanks. Some of the water baffles for the bunker have also been fitted.

There has been further work on Great Western Railway 0-6-2T No. 5643. John Dixon is seen busy with the welder with one of 5643’s side tanks. Some of the water baffles for the bunker have also been fitted. Keith has been fitting new footplate supports to the tender of Great Western Railway ‘Hall’ class 4-6-0 No. 4979 Wootton Hall.

Keith has been fitting new footplate supports to the tender of Great Western Railway ‘Hall’ class 4-6-0 No. 4979 Wootton Hall. Work on refreshing the FRT’s mess room in on the last lap in between the rain showers with Sim applying undercoat yellow to the corner posts.

Work on refreshing the FRT’s mess room in on the last lap in between the rain showers with Sim applying undercoat yellow to the corner posts. There has been more progress with the overhaul of Great Western Railway 0-6-2T No. 5643 over the past couple of weeks. Ian Massey has now removed the second, right hand, cylinder liner, the gouging rods making a spectacular light display.

There has been more progress with the overhaul of Great Western Railway 0-6-2T No. 5643 over the past couple of weeks. Ian Massey has now removed the second, right hand, cylinder liner, the gouging rods making a spectacular light display. Once the top of the liner was cut it was necessary to apply brute force to remove it. John Dixon and Keith are seen hauling it out of the cylinder after Ian Massey had persuaded it to move!

Once the top of the liner was cut it was necessary to apply brute force to remove it. John Dixon and Keith are seen hauling it out of the cylinder after Ian Massey had persuaded it to move! Chris Rycroft has been reaming out stay holes in the side of the firebox, with assistance from John Dixon, using a borrowed air drill.

Chris Rycroft has been reaming out stay holes in the side of the firebox, with assistance from John Dixon, using a borrowed air drill. This piece of equipment proved to be very efficient and, with much more work of this nature required, a search was conducted for a suitable second-hand drill – new drills, if you can find them, are very expensive. Fortunately, Sam and Chris identified such a drill and a price agreed. The drill arrived last Wednesday with Sam seen cutting open the packaging.

This piece of equipment proved to be very efficient and, with much more work of this nature required, a search was conducted for a suitable second-hand drill – new drills, if you can find them, are very expensive. Fortunately, Sam and Chris identified such a drill and a price agreed. The drill arrived last Wednesday with Sam seen cutting open the packaging. This new yellow bit of kit was quickly tested and is now ready for action.

This new yellow bit of kit was quickly tested and is now ready for action. Outside, John Dixon and Ed Tatham have been beavering away on the bunker and tanks, removing rust and, in the case of the bunker water tank, applying fibreglass and two-part epoxy paint sealant. Also trying to avoid the seemingly persistent unsettled weather have been Jon, Sim and Tim during their mission to spruce up the exterior of the mess room. It is hoped to reduce the many shades of grey to one of gloss grey if the weather is fine this next week.

Outside, John Dixon and Ed Tatham have been beavering away on the bunker and tanks, removing rust and, in the case of the bunker water tank, applying fibreglass and two-part epoxy paint sealant. Also trying to avoid the seemingly persistent unsettled weather have been Jon, Sim and Tim during their mission to spruce up the exterior of the mess room. It is hoped to reduce the many shades of grey to one of gloss grey if the weather is fine this next week. Finally, there was a test outing of Borrows 0-4-0 well tank No. 48 of 1906 on Saturday in readiness for its appearance at the RSR’s Gala on the 28th and 29th September. Judging by the smile on owner Phil Steer’s face, the test must have been successful.

Finally, there was a test outing of Borrows 0-4-0 well tank No. 48 of 1906 on Saturday in readiness for its appearance at the RSR’s Gala on the 28th and 29th September. Judging by the smile on owner Phil Steer’s face, the test must have been successful. There was some disappointment on Thursday when the air drill being used to ream out the stay holes on Great Western Railway No. 5643’s firebox didn’t live up to the task. A new drill is being sought for this next week. However, there has been further progress with the cleaning of 5643’s rear water tanks where some two-part epoxy paint will be applied. A coat of bitumastic paint has been painted inside the bunker. Keith has been cutting up steel plate to fit in both 5643’s rear water tank and also 4979’s tender so there will be plenty of work for our welder to do.

There was some disappointment on Thursday when the air drill being used to ream out the stay holes on Great Western Railway No. 5643’s firebox didn’t live up to the task. A new drill is being sought for this next week. However, there has been further progress with the cleaning of 5643’s rear water tanks where some two-part epoxy paint will be applied. A coat of bitumastic paint has been painted inside the bunker. Keith has been cutting up steel plate to fit in both 5643’s rear water tank and also 4979’s tender so there will be plenty of work for our welder to do. Finally, Live Steam had a successful gig at the Engine Inn at Cark-in-Cartmel on Saturday evening, although it was not without incident. Three police vans appeared in the usually sleepy village to attend to a couple of members of the audience who had been ejected for unruly behaviour. Although it is said that they had paid to hire a holiday cottage in the village, it wasn’t required that night as we hear they were given alternative accommodation courtesy of Cumbria Police!

Finally, Live Steam had a successful gig at the Engine Inn at Cark-in-Cartmel on Saturday evening, although it was not without incident. Three police vans appeared in the usually sleepy village to attend to a couple of members of the audience who had been ejected for unruly behaviour. Although it is said that they had paid to hire a holiday cottage in the village, it wasn’t required that night as we hear they were given alternative accommodation courtesy of Cumbria Police! Furness Railway locomotive No. 20 returned to Preston from its slightly extended seaside holiday at Minehead at 9.30 pm on Wednesday evening and was unloaded the following day. There was just time therefore on Friday to put back guard irons, sand pipes and other equipment as well as give it a thorough inspection and clean before it re-entered service on the Ribble Steam Railway on Saturday. Thanks go to Sam, Alan, John and Jack for their help and contributions to ensuring that FR 20 looked sparkling for those who came to ride behind it.

Furness Railway locomotive No. 20 returned to Preston from its slightly extended seaside holiday at Minehead at 9.30 pm on Wednesday evening and was unloaded the following day. There was just time therefore on Friday to put back guard irons, sand pipes and other equipment as well as give it a thorough inspection and clean before it re-entered service on the Ribble Steam Railway on Saturday. Thanks go to Sam, Alan, John and Jack for their help and contributions to ensuring that FR 20 looked sparkling for those who came to ride behind it. Work continues on the overhaul at Preston of Great Western Railway 0-6-2T No. 5643 where Ed has been cleaning out the tanks, a dirty job as you can see from the photographs. Needless to say, he was then accused of giving everyone black looks!

Work continues on the overhaul at Preston of Great Western Railway 0-6-2T No. 5643 where Ed has been cleaning out the tanks, a dirty job as you can see from the photographs. Needless to say, he was then accused of giving everyone black looks! Thursday saw Chris Rycroft, John Dixon and Keith riveting some new steel angle to the frames under where the bunker is situated. John is seen warming up the rivets…

Thursday saw Chris Rycroft, John Dixon and Keith riveting some new steel angle to the frames under where the bunker is situated. John is seen warming up the rivets… ……which can then be seen securely in position.

……which can then be seen securely in position. Some more riveting is still required and Keith is seen here preparing the holes with a drill. The new steel angle can also be seen in situ.

Some more riveting is still required and Keith is seen here preparing the holes with a drill. The new steel angle can also be seen in situ. Finally, Sim and Tim have continued their work on the repaint of the mess room, with Sim seen here giving the roof a coat of paint.

Finally, Sim and Tim have continued their work on the repaint of the mess room, with Sim seen here giving the roof a coat of paint.