Another short update this week – but that doesn’t mean that nothing has been happening.

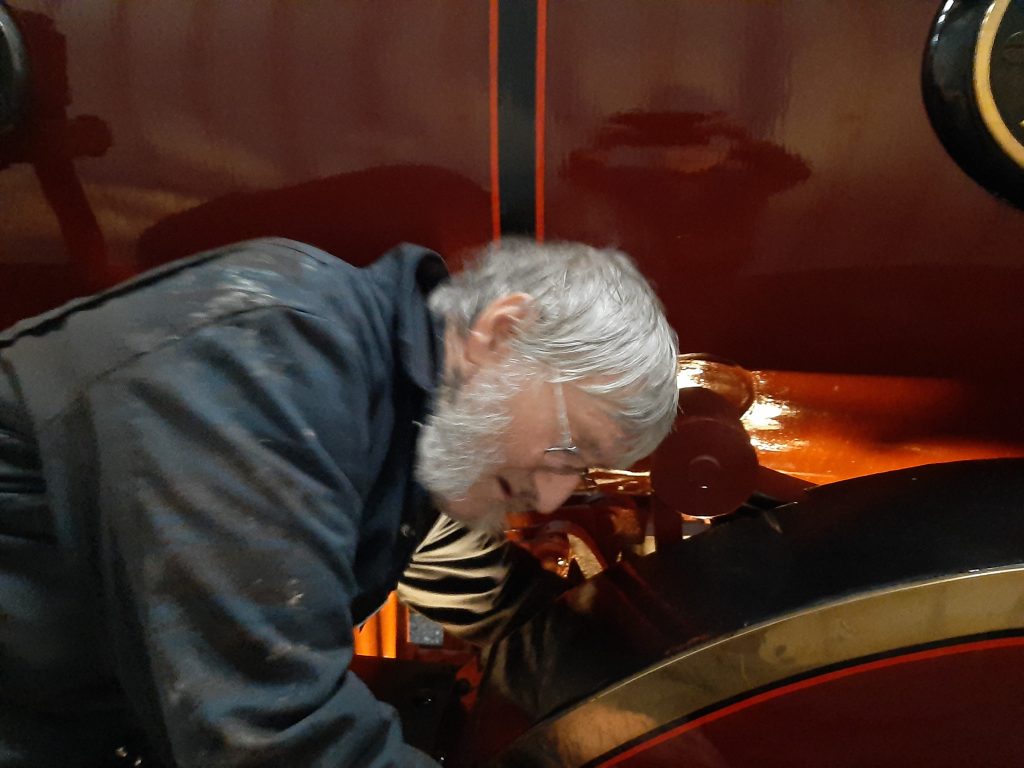

The main news is that a washout of FR 20’s boiler was successfully carried out last Wednesday, the first to be undertaken using the Coventry Climax fire pump that was purchased just before the first lock down. Former members Jon Dixon and Neil Glover, who are used to dealing with fire pumps, came to give us a hand and, after setting everything up carefully, everything worked and went to plan! (How did that happen, you may ask?!!) The photo shows Jon aiming the water into a plug hole in FR 20’s front tubeplate whilst Neil controls the fire pump and Alan inspects the colour of the water running out of the firebox plug holes. The purpose of using the fire pump is that it can deliver water into the boiler at a far greater pressure than from the mains and so be more efficient in removing sludge and scale. The big question that needed answering was whether the pump would be able to lift the feed water from the tender tank through the suction hoses; the answer was a very positive yes. We are grateful to Jon and Neil for their assistance and hope that Jon managed to clean himself up after managing to get himself covered in a mixture of soot and water!

The main news is that a washout of FR 20’s boiler was successfully carried out last Wednesday, the first to be undertaken using the Coventry Climax fire pump that was purchased just before the first lock down. Former members Jon Dixon and Neil Glover, who are used to dealing with fire pumps, came to give us a hand and, after setting everything up carefully, everything worked and went to plan! (How did that happen, you may ask?!!) The photo shows Jon aiming the water into a plug hole in FR 20’s front tubeplate whilst Neil controls the fire pump and Alan inspects the colour of the water running out of the firebox plug holes. The purpose of using the fire pump is that it can deliver water into the boiler at a far greater pressure than from the mains and so be more efficient in removing sludge and scale. The big question that needed answering was whether the pump would be able to lift the feed water from the tender tank through the suction hoses; the answer was a very positive yes. We are grateful to Jon and Neil for their assistance and hope that Jon managed to clean himself up after managing to get himself covered in a mixture of soot and water!

There was progress with Caliban and Fluff during the week, while John Dixon, Ed and Tim made further inroads into removing the previous bonding paste from the roof of GER Royal Saloon No. 5. Also, Keith managed to fit Wootton Hall‘s tender vacuum cylinder into place.

Both GWR 0-6-2T 5643 and ‘Austerity’ 0-6-0ST Cumbria were due to haul trains at Bury and Embsay respectively over the weekend and we are pleased to be able to include some seasonal photos of Cumbria in action courtesy of Matt Anderson of the Embsay & Bolton Abbey Steam Railway……

… and to share again (we did already on the FRT Twitter account) this lovely picture of 5643.

Finally, Alan informs us that the latest edition of The Iron Horse magazine is ready to go to the printer and, all being well, the aim is to post it out to members before Christmas.

Phil Bell and John Davis made further progress with Fluff by re-fitting the rods, which went back on with little bother once the wheels had been lined up. We still await the new cab roof and there are no doubt many other jobs to complete.

Phil Bell and John Davis made further progress with Fluff by re-fitting the rods, which went back on with little bother once the wheels had been lined up. We still await the new cab roof and there are no doubt many other jobs to complete. Should John and Phil ever run out of work, we can surely point them towards the roof of GER No.5 where, having removed the lamp housings, vents, conduit and canvas, there is now the tedious task of removing the canvas bonding compound, some of which is resolutely stuck fast to the wooden roof planks. Ed and John Dixon have made a start but it seems that heat guns are the solution to the problem.

Should John and Phil ever run out of work, we can surely point them towards the roof of GER No.5 where, having removed the lamp housings, vents, conduit and canvas, there is now the tedious task of removing the canvas bonding compound, some of which is resolutely stuck fast to the wooden roof planks. Ed and John Dixon have made a start but it seems that heat guns are the solution to the problem. With the fire pump now in operational order, we are now looking towards what we need to do to use it to conduct a high pressure boiler wash out. In advance of a gathering this next Wednesday to progress the project, Alan has come up with a modified hose branch which should manage to aim the water to all the required nooks and crannies on FR 20’s boiler. With the right hand piston rod cotter adjustments now completed we will be able to move the loco outside the shed with the first job being to drop the existing water in the boiler.

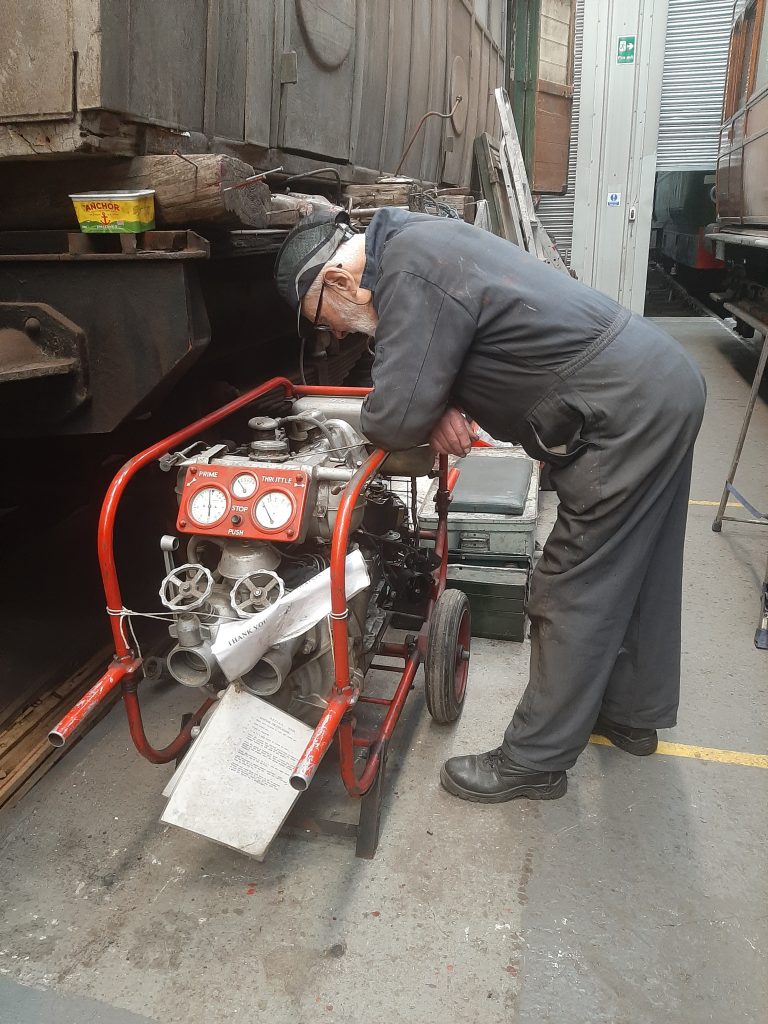

With the fire pump now in operational order, we are now looking towards what we need to do to use it to conduct a high pressure boiler wash out. In advance of a gathering this next Wednesday to progress the project, Alan has come up with a modified hose branch which should manage to aim the water to all the required nooks and crannies on FR 20’s boiler. With the right hand piston rod cotter adjustments now completed we will be able to move the loco outside the shed with the first job being to drop the existing water in the boiler. At 14.45 on Friday, the peace of the FRT shed was shattered without warning by the earthy roar of a Coventry Climax engine, announcing to all that the three days of work that Roger had expended on the fire pump had been successful. Well done, Roger! We now need to see how the machine copes with washing out a locomotive boiler!

At 14.45 on Friday, the peace of the FRT shed was shattered without warning by the earthy roar of a Coventry Climax engine, announcing to all that the three days of work that Roger had expended on the fire pump had been successful. Well done, Roger! We now need to see how the machine copes with washing out a locomotive boiler! There has been further progress on clearing the roof of GER Royal Saloon No. 5 with Ed and John seen here working in tandem on the magic carpet to remove the remaining rain strips and canvas.

There has been further progress on clearing the roof of GER Royal Saloon No. 5 with Ed and John seen here working in tandem on the magic carpet to remove the remaining rain strips and canvas. Fred has once again been cleaning up the torpedo vents – usually two in a day. Yet more cup wire brushes to order!

Fred has once again been cleaning up the torpedo vents – usually two in a day. Yet more cup wire brushes to order! Anne and Phil Burton have been making steady progress on the upholstery in GER No. 5. They have obtained some cheaper moquette with which to practice on re-covering the cushions.

Anne and Phil Burton have been making steady progress on the upholstery in GER No. 5. They have obtained some cheaper moquette with which to practice on re-covering the cushions. The finished article looks pretty good. They aim to have one more practice cushion before the selected, rather more expensive, moquette is purchased, which we feel will be more appropriate for a royal saloon.

The finished article looks pretty good. They aim to have one more practice cushion before the selected, rather more expensive, moquette is purchased, which we feel will be more appropriate for a royal saloon. More progress has been made with fitting the cladding on 4979 Wootton Hall’s boiler. It is a team job to get the sheets on top of the boiler as can be seen here.

More progress has been made with fitting the cladding on 4979 Wootton Hall’s boiler. It is a team job to get the sheets on top of the boiler as can be seen here. The third sheet on the right hand side has now been fitted.

The third sheet on the right hand side has now been fitted. Meanwhile, Tim has been devoting his time recently to tidying up 4979’s fabricated cab side stanchions with filler so that they look more like Swindon manufactured pressings. The cab sides are also starting to receive attention where they have suffered after having been exposed to 50 years of the elements.

Meanwhile, Tim has been devoting his time recently to tidying up 4979’s fabricated cab side stanchions with filler so that they look more like Swindon manufactured pressings. The cab sides are also starting to receive attention where they have suffered after having been exposed to 50 years of the elements. Elsewhere, Ade has, amongst other things, been fitting brake blocks to Caliban’s chassis. Alan and Sam have been adjusting the miscreant piston rod cotter on FR 20. Incidentally, there is now video footage available from a cab mounted camera of FR 20’s first trip in service on the RSR after overhaul:

Elsewhere, Ade has, amongst other things, been fitting brake blocks to Caliban’s chassis. Alan and Sam have been adjusting the miscreant piston rod cotter on FR 20. Incidentally, there is now video footage available from a cab mounted camera of FR 20’s first trip in service on the RSR after overhaul: We are pleased to report further progress with Wootton Hall with the wooden packing on the tender frames dovetailed together and all but complete. Once finished it will then be possible to plan lifting the tender tank on to the frames where it can be more easily repaired inside the shed.

We are pleased to report further progress with Wootton Hall with the wooden packing on the tender frames dovetailed together and all but complete. Once finished it will then be possible to plan lifting the tender tank on to the frames where it can be more easily repaired inside the shed. The opportunity was taken last Wednesday to test the tender brake cylinder which has been refurbished. The cylinder was taken around to the Ribble Steam Railway running shed where it was connected up to vacuum braked diesel shunter Stanlow. Keith and Duncan Sawyer are seen ensuring the connections are correct.

The opportunity was taken last Wednesday to test the tender brake cylinder which has been refurbished. The cylinder was taken around to the Ribble Steam Railway running shed where it was connected up to vacuum braked diesel shunter Stanlow. Keith and Duncan Sawyer are seen ensuring the connections are correct. The pipework involved is seen here and it appears that the test was successful.

The pipework involved is seen here and it appears that the test was successful. Last Wednesday also saw our folk group, Live Steam, performing on platform 3 at Lancaster station as part of the finale to the Furness Railway 175 celebrations. The lads are seen here sitting down for their lengthy second set of railway songs.

Last Wednesday also saw our folk group, Live Steam, performing on platform 3 at Lancaster station as part of the finale to the Furness Railway 175 celebrations. The lads are seen here sitting down for their lengthy second set of railway songs. First, Keith had to remove handrail stanchions to enable the cladding to be fitted. Needless to say, after many years out in the open, the stanchions needed some heat treatment before they could be unscrewed and removed.

First, Keith had to remove handrail stanchions to enable the cladding to be fitted. Needless to say, after many years out in the open, the stanchions needed some heat treatment before they could be unscrewed and removed. Although of fairly thin steel sheet, they are heavier than you would think when it comes to lifting them up on to a locomotive boiler.

Although of fairly thin steel sheet, they are heavier than you would think when it comes to lifting them up on to a locomotive boiler. The photos show the number of people required for lifting the second of the right hand cladding sheets.

The photos show the number of people required for lifting the second of the right hand cladding sheets. Sam stands alongside the second fitted sheet.

Sam stands alongside the second fitted sheet. With the upper superstructure of Fluff now virtually complete, Phil and John Davis have been turning their attention to the side rods, which seem to have suffered from the weather on one side. However, after the application of a thin layer of filler applied by Tim, John was soon able to apply a coat of primer.

With the upper superstructure of Fluff now virtually complete, Phil and John Davis have been turning their attention to the side rods, which seem to have suffered from the weather on one side. However, after the application of a thin layer of filler applied by Tim, John was soon able to apply a coat of primer. Finally, the saga of the fire pump continues with Roger spending some time trying to obtain a spark from the plugs. The pump has been brought into the FRT shed where it is hoped the drier atmosphere will assist the magneto to do its job.

Finally, the saga of the fire pump continues with Roger spending some time trying to obtain a spark from the plugs. The pump has been brought into the FRT shed where it is hoped the drier atmosphere will assist the magneto to do its job.