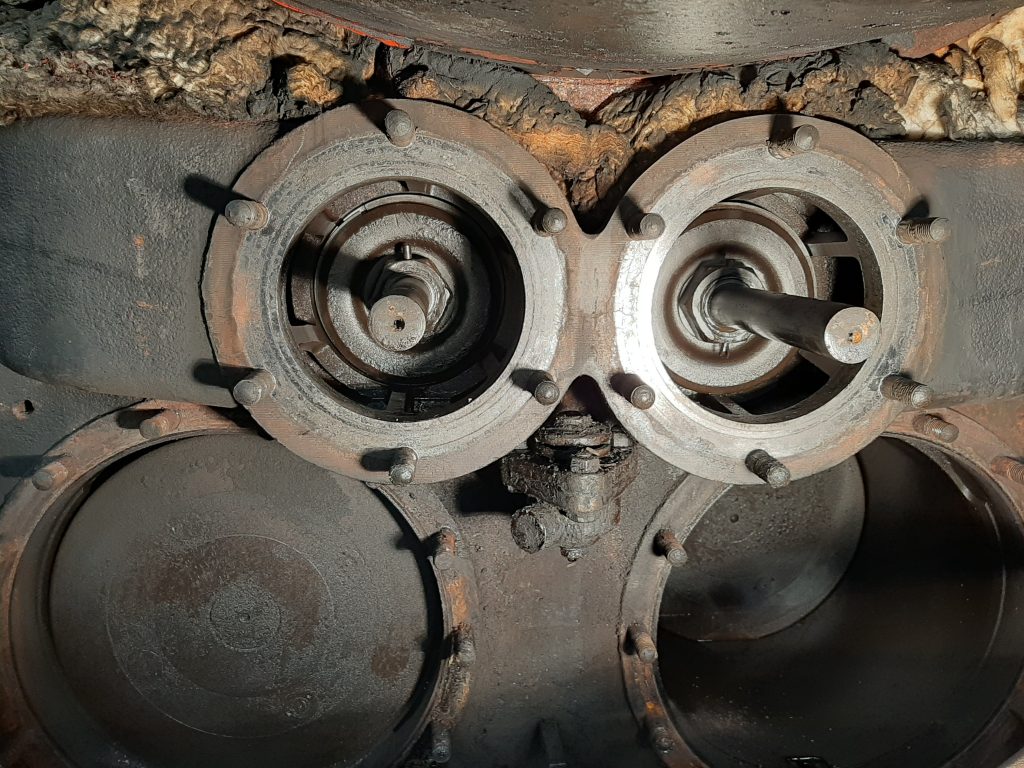

The maintenance work on 5643 has continued with the valves now removed for cleaning. Keith has been measuring them to ensure that they are still a good fit with the valve liners.

The maintenance work on 5643 has continued with the valves now removed for cleaning. Keith has been measuring them to ensure that they are still a good fit with the valve liners.

Elsewhere the less glamorous work of cleaning has made more headway with Phil Bell trying to get to the far distant parts in the motion.

Elsewhere the less glamorous work of cleaning has made more headway with Phil Bell trying to get to the far distant parts in the motion.

John Davis also found himself doing some cleaning, probably wishing he hadn’t chosen to wear such a light-coloured T shirt!

John Davis also found himself doing some cleaning, probably wishing he hadn’t chosen to wear such a light-coloured T shirt!

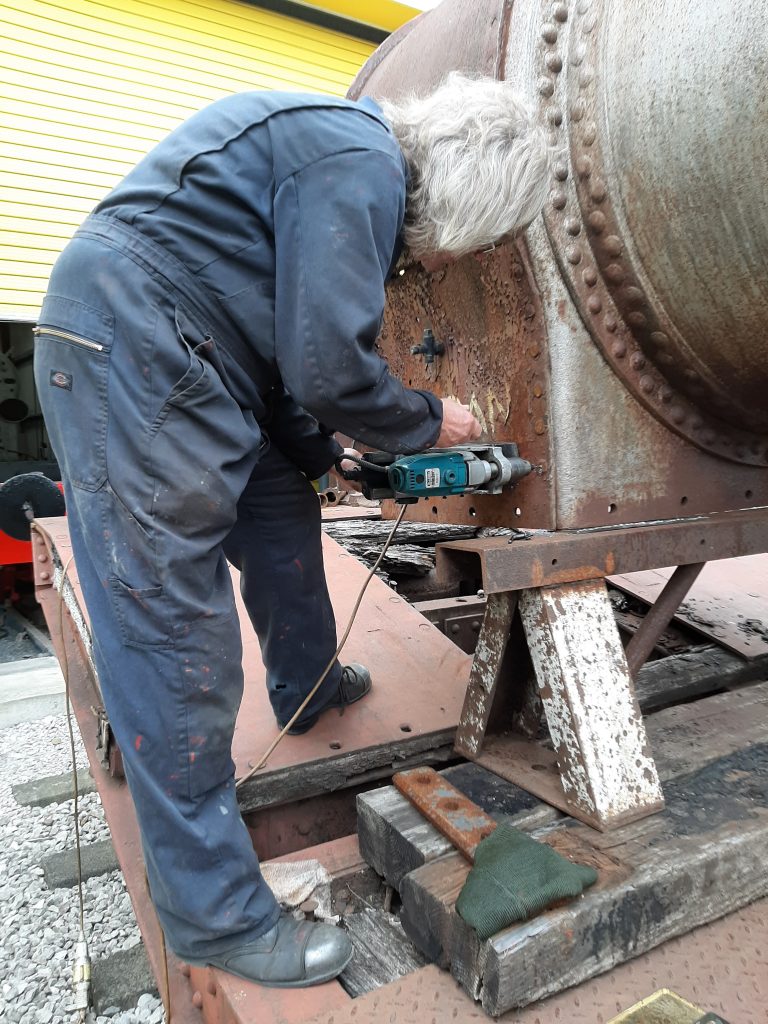

Whilst Fluff has temporarily been banished to the unheated part of the FRT shed during 5643’s stay, the little diesel hasn’t been forgotten and Keith and Phil are seen preparing to cut a new piece of steel to replace this old rather moth-eaten relic.

Whilst Fluff has temporarily been banished to the unheated part of the FRT shed during 5643’s stay, the little diesel hasn’t been forgotten and Keith and Phil are seen preparing to cut a new piece of steel to replace this old rather moth-eaten relic.

The weather last Friday was pretty good so John Dixon took the opportunity to clean out FR 20’s ashpan prior to giving it a new coat of paint.

The weather last Friday was pretty good so John Dixon took the opportunity to clean out FR 20’s ashpan prior to giving it a new coat of paint.

Fred came in on Friday again wielding his trusty angle grinder with cup wire brush. This time he joined Tim in removing old brittle paint from FR 20’s right hand valance.

Fred came in on Friday again wielding his trusty angle grinder with cup wire brush. This time he joined Tim in removing old brittle paint from FR 20’s right hand valance.

Ade, Keith and Tim had the chance on Saturday to reacquaint themselves with the controls of steam locomotive Courageous as the Ribble Steam Railway ran some proving trains which were also used to recertify train crew in anticipation of operating some train services in October. The day also saw the introduction of temperature testing of volunteers in order to reduce the risk of transmission of Covid-19. There was general approval of this initiative by FRT volunteers last Friday and so the FRT has acquired a similar testing device which will be brought into use this week.

Alan and Ade conducted a further hydraulic test on FR 20’s boiler on Wednesday after successfully making a new dome cover joint last week and Ade can be seen here working up some pressure. A formal test for the boiler surveyor has been booked for the 12th October.

Alan and Ade conducted a further hydraulic test on FR 20’s boiler on Wednesday after successfully making a new dome cover joint last week and Ade can be seen here working up some pressure. A formal test for the boiler surveyor has been booked for the 12th October. John Dixon finished finding or making the new studs for FR 20’s steam and blast pipes and had them fitted on Wednesday. He is seen here applying a die nut to one of the studs.

John Dixon finished finding or making the new studs for FR 20’s steam and blast pipes and had them fitted on Wednesday. He is seen here applying a die nut to one of the studs. Friday saw young Matthew join the gang having started a fabrication and welding course at college. He was quickly put to good use operating the hoist to lift one of the new engine springs into position for another test fit.

Friday saw young Matthew join the gang having started a fabrication and welding course at college. He was quickly put to good use operating the hoist to lift one of the new engine springs into position for another test fit. Keith has removed 5643’s valve and cylinder covers as he starts the valve and piston examination.

Keith has removed 5643’s valve and cylinder covers as he starts the valve and piston examination.

Finally, Fred was with us on Friday to continue his work cleaning up and painting the cab floor metalwork.

Finally, Fred was with us on Friday to continue his work cleaning up and painting the cab floor metalwork. Alan and Ade removed the dome cover from FR 20’s boiler with the assistance of Ribble Rail staff and the hi-ab. They then prepared a new joint before the dome cover was replaced and fastened down.

Alan and Ade removed the dome cover from FR 20’s boiler with the assistance of Ribble Rail staff and the hi-ab. They then prepared a new joint before the dome cover was replaced and fastened down. John Dixon continued and completed his work drilling out wasted or broken studs which secure the blastpipe and main steam pipe.

John Dixon continued and completed his work drilling out wasted or broken studs which secure the blastpipe and main steam pipe. Alan had picked up Caliban‘s valve spindles from IRS Surfacing Technologies at Burscough. They had been metal sprayed to counter corrosion and then ground back to size. From the finished job they looked brand new.

Alan had picked up Caliban‘s valve spindles from IRS Surfacing Technologies at Burscough. They had been metal sprayed to counter corrosion and then ground back to size. From the finished job they looked brand new. There has been more attention given to 5643 with Paul Balshaw cleaning up the rods.

There has been more attention given to 5643 with Paul Balshaw cleaning up the rods. Phil Bell focussed his attention beneath the cab floor, which has been removed to allow access.

Phil Bell focussed his attention beneath the cab floor, which has been removed to allow access. Fred came in on Friday to clean up some of the cab floor steelwork

Fred came in on Friday to clean up some of the cab floor steelwork Keith has given John Dixon the job of refurbishing a second-hand GWR cab seat and then creating another for Wootton Hall.

Keith has given John Dixon the job of refurbishing a second-hand GWR cab seat and then creating another for Wootton Hall. Lunchtimes these days are a little strange with members spacing themselves out either in the mess room or the shed. Here we see John Davis, Paul Newton and Phil Bell suitably socially distanced (no, we didn’t say spaced out!).

Lunchtimes these days are a little strange with members spacing themselves out either in the mess room or the shed. Here we see John Davis, Paul Newton and Phil Bell suitably socially distanced (no, we didn’t say spaced out!). The steam chest cover and tail rod bushes for the valve spindles have been re-fitted to FR 20, with Alan seen here at work on the matter.

The steam chest cover and tail rod bushes for the valve spindles have been re-fitted to FR 20, with Alan seen here at work on the matter. A number of steam pipe and blast pipe studs need to be replaced either through wastage or breakage. John Dixon tried to remove one of the blast pipe studs using some heat.

A number of steam pipe and blast pipe studs need to be replaced either through wastage or breakage. John Dixon tried to remove one of the blast pipe studs using some heat. Unfortunately, the heat treatment failed to make any difference so John is seen here (successfully) drilling out one of the broken studs.

Unfortunately, the heat treatment failed to make any difference so John is seen here (successfully) drilling out one of the broken studs. The magnetic drill was much in demand last Wednesday when Ade also took the opportunity to start drilling out smokebox rivets on Caliban‘s boiler.

The magnetic drill was much in demand last Wednesday when Ade also took the opportunity to start drilling out smokebox rivets on Caliban‘s boiler. There has been further cleaning of 5643’s motion and frames.

There has been further cleaning of 5643’s motion and frames. 5643’s main brake shaft was removed by team Bell and Davis with a little help from Keith and the lifting table. It is a sizeable chunk of metal that has to be respected!

5643’s main brake shaft was removed by team Bell and Davis with a little help from Keith and the lifting table. It is a sizeable chunk of metal that has to be respected! Continuing Great Western news, Keith has been spending more time shaping the new injector delivery pipework for Wootton Hall.

Continuing Great Western news, Keith has been spending more time shaping the new injector delivery pipework for Wootton Hall.