This week we focus on Furness Railway No. 20 as its lengthy overhaul progresses towards a conclusion.

On Tuesday, the loco received its final formal cold inspection by the boiler surveyor when it was deemed to be ready for a steam test.

With Adrian available on Wednesday, it was sensible to conduct a shunt of the FRT shed which saw FR 20 moved off the pit to be replaced by Great Eastern Railway Royal Saloon No. 5.

With Adrian available on Wednesday, it was sensible to conduct a shunt of the FRT shed which saw FR 20 moved off the pit to be replaced by Great Eastern Railway Royal Saloon No. 5.

Once the remaining washout plugs and mudhole doors had been fitted to the firebox, FR 20 was sent around to the running shed for the tender to be filled with coal and the boiler with water.

Once the remaining washout plugs and mudhole doors had been fitted to the firebox, FR 20 was sent around to the running shed for the tender to be filled with coal and the boiler with water.

There was then a trip to the water tower to fill the tender tank with water before the loco was returned to the front of the FRT shed. Most of Friday was spent on finishing jobs in the smokebox.

First the blast pipe was lifted and fitted before John Dixon mixed some refractory concrete to seal the base of the smokebox.

First the blast pipe was lifted and fitted before John Dixon mixed some refractory concrete to seal the base of the smokebox.  Finally, the new blower pipe was then fitted.

Finally, the new blower pipe was then fitted.

Saturday morning saw the engine pulled out of the shed by Hawthorn Leslie 0-6-0ST Linda, prior to the first train of the RSR’s weekend Steam Gala. It was at this point that no one could come up with any more jobs that needed to be done and, at 10.12, Tim duly struck a match to start the process of raising steam.

Saturday morning saw the engine pulled out of the shed by Hawthorn Leslie 0-6-0ST Linda, prior to the first train of the RSR’s weekend Steam Gala. It was at this point that no one could come up with any more jobs that needed to be done and, at 10.12, Tim duly struck a match to start the process of raising steam.

Plenty of time was spent in slowly warming the boiler, the fire being very gradually built up and spread around the firebox. Meanwhile Tim conducted a few tours of the FRT shed for those visitors to the RSR Gala who wanted a closer look at FR 20 and to view progress on Wootton Hall and Caliban.

Plenty of time was spent in slowly warming the boiler, the fire being very gradually built up and spread around the firebox. Meanwhile Tim conducted a few tours of the FRT shed for those visitors to the RSR Gala who wanted a closer look at FR 20 and to view progress on Wootton Hall and Caliban.

By late afternoon both of FR 20’s injectors had been tested and the safety valves adjusted.

By late afternoon both of FR 20’s injectors had been tested and the safety valves adjusted.  Time then to reverse FR 20 back into the shed and close the doors.

Time then to reverse FR 20 back into the shed and close the doors.

Sunday morning saw John Dixon, Alan and Tim reconvene to undertake some fettling jobs, including the fitting of a couple of new joints on the right hand injector delivery pipe, before raising steam once again. The remedial works appeared to be successful and, after a gentle trip up and down the yard, FR 20 was duly viewed as being ready for a formal ‘in steam’ inspection by the boiler surveyor.

A final reminder now that the Annual General Meeting of the Furness Railway Trust will take place in the FRT shed tomorrow night, Tuesday, at 7.30 pm. We have been promised cake once the contents of the Trustees’ Annual Report and Accounts have been digested and approved!

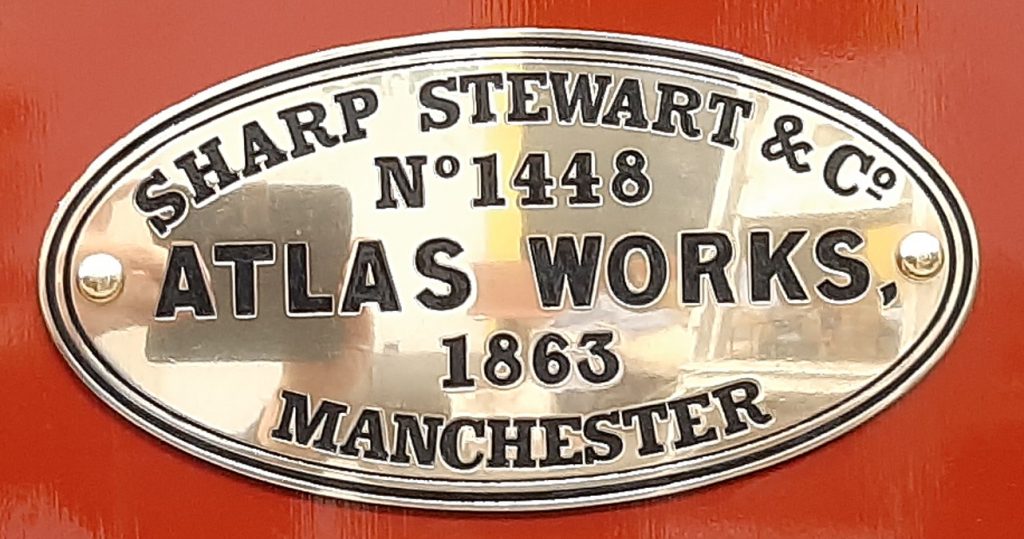

The final jobs on Furness Railway No. 20 are gradually being knocked off the ‘to do’ list. The black paintwork on the works plates has been renewed by Neil and the plates were re-fitted on Wednesday.

The final jobs on Furness Railway No. 20 are gradually being knocked off the ‘to do’ list. The black paintwork on the works plates has been renewed by Neil and the plates were re-fitted on Wednesday. Ron Crowe refitted the sand pipes while Paul Balshaw gave the loco another clean in readiness for the forthcoming ‘volunteer open day’.

Ron Crowe refitted the sand pipes while Paul Balshaw gave the loco another clean in readiness for the forthcoming ‘volunteer open day’. Alan and Sam spent quite some time modifying and then fitting the main steam pipe in the smokebox.

Alan and Sam spent quite some time modifying and then fitting the main steam pipe in the smokebox. John Dixon has made some clamps to retain the boiler water gauge drain pipes in place – another of those jobs that has taken over twenty years to achieve!

John Dixon has made some clamps to retain the boiler water gauge drain pipes in place – another of those jobs that has taken over twenty years to achieve! Ade caught Phil Bell and John Davis working on the right hand side of Fluff’s bonnet on Wednesday.

Ade caught Phil Bell and John Davis working on the right hand side of Fluff’s bonnet on Wednesday. We had a delivery of newly shaped steel plate on Friday from which Keith is going to construct a new water take off box which will sit below Wootton Hall’s tender tank when completed.

We had a delivery of newly shaped steel plate on Friday from which Keith is going to construct a new water take off box which will sit below Wootton Hall’s tender tank when completed. FR 20’s new blower ring has been fabricated by John Dixon and is seen alongside the old ring which had certainly had its day.

FR 20’s new blower ring has been fabricated by John Dixon and is seen alongside the old ring which had certainly had its day. John then set about drilling the new holes which, at 1/8th”, are slightly smaller than the previous holes which had opened out naturally beyond their original size.

John then set about drilling the new holes which, at 1/8th”, are slightly smaller than the previous holes which had opened out naturally beyond their original size. Alan and Sam have been working on modifying the main steam pipe. Sam is seen opening out the holes in one end of the pipe to accommodate the new studs on the steam chest.

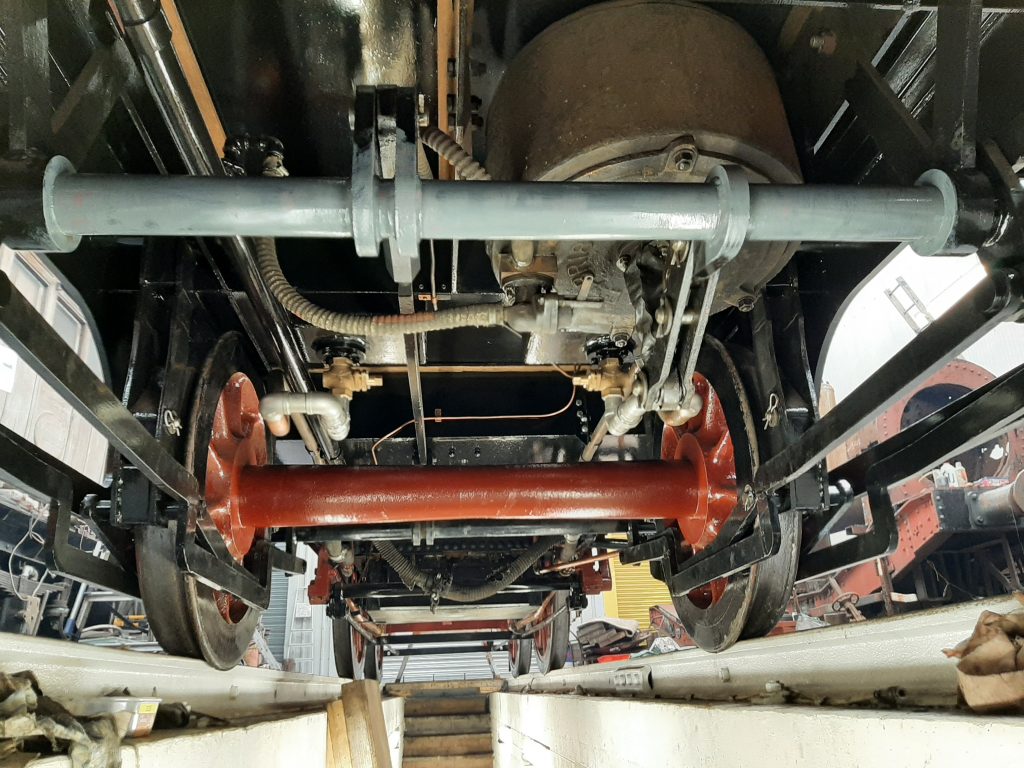

Alan and Sam have been working on modifying the main steam pipe. Sam is seen opening out the holes in one end of the pipe to accommodate the new studs on the steam chest. Tim has been putting the finishing touches to the paintwork underneath the tender which, along with some new pipework, looks very smart.

Tim has been putting the finishing touches to the paintwork underneath the tender which, along with some new pipework, looks very smart. Ade spent Wednesday raising Caliban‘s frames so that the wheels could be rolled underneath (hope the wheels are the right way round, Ade!), and then lowering the frames back down again.

Ade spent Wednesday raising Caliban‘s frames so that the wheels could be rolled underneath (hope the wheels are the right way round, Ade!), and then lowering the frames back down again. After some adjustment with the help of a traversing jack, the frames finally came down in the right place, between the wheels.

After some adjustment with the help of a traversing jack, the frames finally came down in the right place, between the wheels. The left hand side of Fluff‘s engine compartment bonnet is now visibly complete.

The left hand side of Fluff‘s engine compartment bonnet is now visibly complete. John Davis has set about priming an angle to support the right hand side panels.

John Davis has set about priming an angle to support the right hand side panels. Wootton Hall’s tender vacuum cylinder has been lowered into position.

Wootton Hall’s tender vacuum cylinder has been lowered into position. Finally, Keith has now manoeuvred the brake shaft adjacent to the cylinder into position ready for fitting.

Finally, Keith has now manoeuvred the brake shaft adjacent to the cylinder into position ready for fitting. The new water fittings and pipework underneath FR 20’s tender have now been fitted by John Dixon who has now been concentrating his attention on fabricating a new blower pipe for the engine.

The new water fittings and pipework underneath FR 20’s tender have now been fitted by John Dixon who has now been concentrating his attention on fabricating a new blower pipe for the engine. The corrosion on the underside of the old blower pipe can clearly be seen.

The corrosion on the underside of the old blower pipe can clearly be seen. The jigsaw that is Fluff‘s bonnet continues to come together with Phil Bell assembling some more panels.

The jigsaw that is Fluff‘s bonnet continues to come together with Phil Bell assembling some more panels.