It has been another hectic week at Preston.

There was an urgent need to put GWR 0-6-0T No. 5643 back together in time for yesterday, Monday, when a Reid Freight transporter was due to take it to Bury for a period of hire to the East Lancashire Railway.

The re-assembly of the brake gear was finally completed and Phil Bell is seen here giving the turnbuckle an inspection.

The re-assembly of the brake gear was finally completed and Phil Bell is seen here giving the turnbuckle an inspection.

Keith assembled the front right hand valve cladding.

Keith assembled the front right hand valve cladding.

He then tackled the installation of the new cab floor

He then tackled the installation of the new cab floor

Paul Newton cleaned the copper pipework.

Paul Newton cleaned the copper pipework.

Phil Bell then touched up the black paint on the brass numberplates.

Phil Bell then touched up the black paint on the brass numberplates.

Finally, Keith put back the cab fittings which had been removed to allow the fitting of three new stays. All that was necessary now was to oil around and assist Adrian in shunting the locomotive to the front of the FRT shed.  5643 was moved around to the unloading road on Monday morning ready for loading on to the transporter, which arrived just after 10.30.

5643 was moved around to the unloading road on Monday morning ready for loading on to the transporter, which arrived just after 10.30.

A couple of hours later 5643 was ready for the road, but shortly before departure a consignment of castings arrived from the Severn Valley Railway, and it was possible to load 5643’s new replacement brake blocks on to the well of the transporter. They call it ‘just in time’ in industry, but this was rather close to call!

A couple of hours later 5643 was ready for the road, but shortly before departure a consignment of castings arrived from the Severn Valley Railway, and it was possible to load 5643’s new replacement brake blocks on to the well of the transporter. They call it ‘just in time’ in industry, but this was rather close to call!

Time then to turn attention to Furness Railway No. 20’s boiler. A test steaming had taken place last Wednesday which was satisfactory apart from the fact that some priming out of the safety valves took place because the boiler was tilted forward on the lowmac.

The alignment of the boiler was corrected last Friday, but this meant that the safety valves could only be erected after the boiler had left the running shed on the day of the steaming for the boiler surveyor in order to avoid a conflict with the shed door!  Adrian duly left his bed well before daylight yesterday to arrive at Preston at 07.10 to draw the boiler out of the shed and to light the fire.

Adrian duly left his bed well before daylight yesterday to arrive at Preston at 07.10 to draw the boiler out of the shed and to light the fire.

Alan, John Dixon, and Sam Crawley duly appeared to assist which mostly consisting of breaking up wood from the RSR’s huge wood pile in order to feed FR 20’s voracious firebox.

Alan, John Dixon, and Sam Crawley duly appeared to assist which mostly consisting of breaking up wood from the RSR’s huge wood pile in order to feed FR 20’s voracious firebox.

We are pleased to be able to report that 120 psi was achieved just before 2 pm and in good time for boiler surveyor to conduct his inspection….

We are pleased to be able to report that 120 psi was achieved just before 2 pm and in good time for boiler surveyor to conduct his inspection….  before giving it the thumbs up.

before giving it the thumbs up.

The gang is seen here in celebratory move with Alan Bennett.

The gang is seen here in celebratory move with Alan Bennett.

Amongst the castings received from the Severn Valley Railway was a new vacuum cylinder for Wootton Hall’s tender which will now need to be machined.

Finally, there has been good news from Embsay today in that Cumbria passed its annual steam test for the boiler surveyor.

Tonight the Trustees are meeting virtually by Zoom. The biggest issue will be how to devour Alison’s virtual sandwiches!

FR 20’s boiler is now ready for a fire to be lit after more preparatory work was carried out on it last week in the RSR running shed. The valves were lapped in after the seats had been re-fitted on to the dome. This took quite some time, but patience is a virtue when working on steam locomotives! The fitting of the gauge glasses, pressure gauge and safety valve springs followed along with a minor adjustment to one of the firebars (it conflicted with one of the new patch screws) and it is intended to light a fire this next Wednesday.

FR 20’s boiler is now ready for a fire to be lit after more preparatory work was carried out on it last week in the RSR running shed. The valves were lapped in after the seats had been re-fitted on to the dome. This took quite some time, but patience is a virtue when working on steam locomotives! The fitting of the gauge glasses, pressure gauge and safety valve springs followed along with a minor adjustment to one of the firebars (it conflicted with one of the new patch screws) and it is intended to light a fire this next Wednesday. Back in the FRT shed, John Dixon painstakingly removed the screws holding the brass numbers on the front buffer beams; these hadn’t been moved for over twenty years so it provided quite a challenge.

Back in the FRT shed, John Dixon painstakingly removed the screws holding the brass numbers on the front buffer beams; these hadn’t been moved for over twenty years so it provided quite a challenge. However, the front buffer beam was finally ready for Tim to start a refresh of the paintwork.

However, the front buffer beam was finally ready for Tim to start a refresh of the paintwork. The valances have now been primed following the removal of the old paint.

The valances have now been primed following the removal of the old paint. Work continued on Fluff with John Davis drilling holes in a new cab sheet to accommodate the re-used angle support.

Work continued on Fluff with John Davis drilling holes in a new cab sheet to accommodate the re-used angle support. The wood for 5643’s new cab floor arrived last Wednesday and RSR’s joiner, John Morgan, kindly came in on Saturday to plane and cut it to size.

The wood for 5643’s new cab floor arrived last Wednesday and RSR’s joiner, John Morgan, kindly came in on Saturday to plane and cut it to size.

Keith is seen here under the loco fitting one of the last bolts to the brake gear.

Keith is seen here under the loco fitting one of the last bolts to the brake gear. There has also been a bit of progress to report with Wootton Hall where the new (shrink wrapped) replacement valve liners have finally arrived after having been delayed by the pandemic. The liners will need to be machined and then, themselves, shrink fitted when ready.

There has also been a bit of progress to report with Wootton Hall where the new (shrink wrapped) replacement valve liners have finally arrived after having been delayed by the pandemic. The liners will need to be machined and then, themselves, shrink fitted when ready. Work has continued on the overhaul of Furness Railway No. 20 where preparations are being made for an out-of-frames steaming of the boiler on the 16th November. In deference to the fact that the boiler is sitting on Dave Watkins’ lowmac, we will be doing our best not to set fire to its wooden decking! The first stage to protect it was to remove the wooden packing beneath the firebox (old sleepers) and replace it with a purpose built steel trestle. “A ten minute job,” said an optimistic Adrian as he rolled up with the new trestle, but if truth be told it took a good 25 minutes for Ade, John and Tim to jack up the boiler and fit the new trestle into position, exerting a fair amount of ‘grunt’ along the way.

Work has continued on the overhaul of Furness Railway No. 20 where preparations are being made for an out-of-frames steaming of the boiler on the 16th November. In deference to the fact that the boiler is sitting on Dave Watkins’ lowmac, we will be doing our best not to set fire to its wooden decking! The first stage to protect it was to remove the wooden packing beneath the firebox (old sleepers) and replace it with a purpose built steel trestle. “A ten minute job,” said an optimistic Adrian as he rolled up with the new trestle, but if truth be told it took a good 25 minutes for Ade, John and Tim to jack up the boiler and fit the new trestle into position, exerting a fair amount of ‘grunt’ along the way.

John Dixon has continued his work in preparing new and second hand dome headed bolts for fitting to FR 20’s chimney, smokebox and frames. The are seen here neatly painted and laid out ready for action.

John Dixon has continued his work in preparing new and second hand dome headed bolts for fitting to FR 20’s chimney, smokebox and frames. The are seen here neatly painted and laid out ready for action. Alan, meanwhile, has been applying some emery paper to clean up the recently machined valve seats.

Alan, meanwhile, has been applying some emery paper to clean up the recently machined valve seats. Work on refurbishing the dome cover has also progressed, with Fred seen here finding a great way to self-isolate whilst cleaning the internal surfaces!

Work on refurbishing the dome cover has also progressed, with Fred seen here finding a great way to self-isolate whilst cleaning the internal surfaces! Keith, continuing his work on 5643, is seen here undertaking the less glamorous job of de-crudding the firehole door support. Keith has also been working with Andy Booth to identify any suspect stays that can be replaced whilst the loco is sidelined for maintenance.

Keith, continuing his work on 5643, is seen here undertaking the less glamorous job of de-crudding the firehole door support. Keith has also been working with Andy Booth to identify any suspect stays that can be replaced whilst the loco is sidelined for maintenance. Finally, we must not forget the continuing efforts to rejuvenate Fluff where Phil and John Davis have fitted the new front cab sheets this week.

Finally, we must not forget the continuing efforts to rejuvenate Fluff where Phil and John Davis have fitted the new front cab sheets this week. Last Wednesday saw the successful transfer of FR 20’s boiler from the FRT shed to the RSR running shed where it can be steamed for the boiler surveyor. Both Keith and Ade were assisting Ribble Rail last week and we see Ade here at the controls of Ribble Railway’s Sentinel Progress during the shunt.

Last Wednesday saw the successful transfer of FR 20’s boiler from the FRT shed to the RSR running shed where it can be steamed for the boiler surveyor. Both Keith and Ade were assisting Ribble Rail last week and we see Ade here at the controls of Ribble Railway’s Sentinel Progress during the shunt. Fluff had to be moved out of the way and is seen here being shunted with Keith on board.

Fluff had to be moved out of the way and is seen here being shunted with Keith on board. The boiler was then released and moved to the west of the site.

The boiler was then released and moved to the west of the site. Alan is seen here preparing the dome to receive the valve seats after machining.

Alan is seen here preparing the dome to receive the valve seats after machining. Back inside the FRT shed John Dixon has been cleaning and painting the base of FR 20’s chimney.

Back inside the FRT shed John Dixon has been cleaning and painting the base of FR 20’s chimney. John then set about making new domed bolts that will secure the smokebox to the frames.

John then set about making new domed bolts that will secure the smokebox to the frames. Fred has now finished cleaning old paint from the engine’s valances.

Fred has now finished cleaning old paint from the engine’s valances. Tim has been busy hand-sanding the dome cover ready for painting.

Tim has been busy hand-sanding the dome cover ready for painting. There has been more work on Fluff including work by John Davis to prime the front cab spectacle plate.

There has been more work on Fluff including work by John Davis to prime the front cab spectacle plate. Over at Embsay work has been taking place on the FRT’s ‘Austerity’

Over at Embsay work has been taking place on the FRT’s ‘Austerity’ A similar refresh is seen here being carried out on the front buffer beam.

A similar refresh is seen here being carried out on the front buffer beam. This is all subject to the availability of Ade who is assisting Ribble Rail this week. Ade is pictured here trying his hand last week with the RSR’s recently acquired four wheel drive fork truck.

This is all subject to the availability of Ade who is assisting Ribble Rail this week. Ade is pictured here trying his hand last week with the RSR’s recently acquired four wheel drive fork truck. Work has continued on some of the smaller jobs on FR 20. Tim has finished painting the modified spring hangers and has also done some careful refurbishment and priming of the tender buffer beam so as to retain appropriate signs of age and work use. John Dixon has straightened up the smokebox lamp bracket.

Work has continued on some of the smaller jobs on FR 20. Tim has finished painting the modified spring hangers and has also done some careful refurbishment and priming of the tender buffer beam so as to retain appropriate signs of age and work use. John Dixon has straightened up the smokebox lamp bracket. John then set about giving the bottom of the ashpan a much-needed clean and paint.

John then set about giving the bottom of the ashpan a much-needed clean and paint. Keith has taken advantage of some better weather to cut some more metal from Wootton Hall‘s tender tank.

Keith has taken advantage of some better weather to cut some more metal from Wootton Hall‘s tender tank. Paul Balshaw has continued buffing up 5643’s rods whilst Phil and John Davis have been busy painting new steelwork for Fluff.

Paul Balshaw has continued buffing up 5643’s rods whilst Phil and John Davis have been busy painting new steelwork for Fluff. Finally, Paul Newton has at last managed to put some gloss paint on the slats for the formerly derelict platform seat.

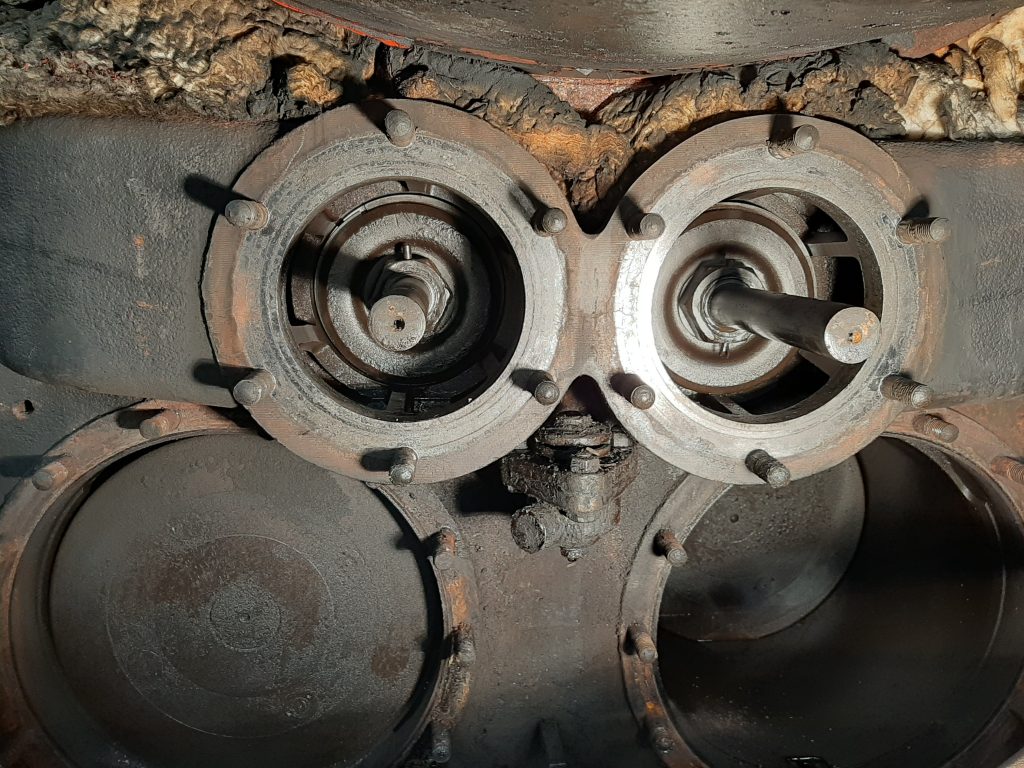

Finally, Paul Newton has at last managed to put some gloss paint on the slats for the formerly derelict platform seat. The cleaning work inside and outside the frames of 5643 has been completed which has allowed work to focus on the valves and pistons. Both pistons have now been split from their respective crossheads and examined by Keith who determined that new piston rings were required. Keith is seen here dressing off one of the rings prior to fitting.

The cleaning work inside and outside the frames of 5643 has been completed which has allowed work to focus on the valves and pistons. Both pistons have now been split from their respective crossheads and examined by Keith who determined that new piston rings were required. Keith is seen here dressing off one of the rings prior to fitting. The heavy work involved in releasing and re-installing the pistons required additional assistance which was provided by George, who came up from Derby on two occasions over the past couple of weeks, however, both pistons are now back in place and connected to the crossheads.

The heavy work involved in releasing and re-installing the pistons required additional assistance which was provided by George, who came up from Derby on two occasions over the past couple of weeks, however, both pistons are now back in place and connected to the crossheads. Work on cleaning up and repainting the cab floor steelwork continues which is Fred’s forte. Fred and John Dixon are seen cleaning up outside the shed on Friday after Fred’s latest work which saw off yet another cup wire brush.

Work on cleaning up and repainting the cab floor steelwork continues which is Fred’s forte. Fred and John Dixon are seen cleaning up outside the shed on Friday after Fred’s latest work which saw off yet another cup wire brush. The end of the main thrust of cleaning on 5643 has enabled Phil, John Davis and Paul to return to the overhaul of Fluff. Phil and John are seen here with yet another new sheet of steel.

The end of the main thrust of cleaning on 5643 has enabled Phil, John Davis and Paul to return to the overhaul of Fluff. Phil and John are seen here with yet another new sheet of steel. We were pleased to see the return of Ed after a short spell in works. He spent a very busy day tidying up the garden area and cutting back undergrowth that was coming through the adjacent fence.

We were pleased to see the return of Ed after a short spell in works. He spent a very busy day tidying up the garden area and cutting back undergrowth that was coming through the adjacent fence. Meanwhile, Alan has cut two new joint rings for the cylinder covers which have been carefully fitted.

Meanwhile, Alan has cut two new joint rings for the cylinder covers which have been carefully fitted.

Alan and Ade then spent most of last Wednesday struggling to fit the left hand cylinder cover, finally succeeding after discovering that one of the studs hadn’t been properly screwed in and was not square with the rest.

Alan and Ade then spent most of last Wednesday struggling to fit the left hand cylinder cover, finally succeeding after discovering that one of the studs hadn’t been properly screwed in and was not square with the rest. We are pleased to report that, after much fine tuning, the new springs are now in place.

We are pleased to report that, after much fine tuning, the new springs are now in place. The annoying slight bulge towards the front of the right hand valance has been removed with the aid of some carefully applied heat and the use of a clamp to straighten the metal.

The annoying slight bulge towards the front of the right hand valance has been removed with the aid of some carefully applied heat and the use of a clamp to straighten the metal. Finally, the ashpan has been cleaned, painted and the ejector ring repaired and re-fitted by John Dixon.

Finally, the ashpan has been cleaned, painted and the ejector ring repaired and re-fitted by John Dixon. Finally, Ade has also spent some time freeing off and adjusting the nuts on Caliban‘s brake rods. Incidentally, contrary to what you might think from the photo, we can confirm that Ade has now had his post lockdown haircut!

Finally, Ade has also spent some time freeing off and adjusting the nuts on Caliban‘s brake rods. Incidentally, contrary to what you might think from the photo, we can confirm that Ade has now had his post lockdown haircut! The maintenance work on 5643 has continued with the valves now removed for cleaning. Keith has been measuring them to ensure that they are still a good fit with the valve liners.

The maintenance work on 5643 has continued with the valves now removed for cleaning. Keith has been measuring them to ensure that they are still a good fit with the valve liners. Elsewhere the less glamorous work of cleaning has made more headway with Phil Bell trying to get to the far distant parts in the motion.

Elsewhere the less glamorous work of cleaning has made more headway with Phil Bell trying to get to the far distant parts in the motion. John Davis also found himself doing some cleaning, probably wishing he hadn’t chosen to wear such a light-coloured T shirt!

John Davis also found himself doing some cleaning, probably wishing he hadn’t chosen to wear such a light-coloured T shirt! Whilst Fluff has temporarily been banished to the unheated part of the FRT shed during 5643’s stay, the little diesel hasn’t been forgotten and Keith and Phil are seen preparing to cut a new piece of steel to replace this old rather moth-eaten relic.

Whilst Fluff has temporarily been banished to the unheated part of the FRT shed during 5643’s stay, the little diesel hasn’t been forgotten and Keith and Phil are seen preparing to cut a new piece of steel to replace this old rather moth-eaten relic. The weather last Friday was pretty good so John Dixon took the opportunity to clean out FR 20’s ashpan prior to giving it a new coat of paint.

The weather last Friday was pretty good so John Dixon took the opportunity to clean out FR 20’s ashpan prior to giving it a new coat of paint. Fred came in on Friday again wielding his trusty angle grinder with cup wire brush. This time he joined Tim in removing old brittle paint from FR 20’s right hand valance.

Fred came in on Friday again wielding his trusty angle grinder with cup wire brush. This time he joined Tim in removing old brittle paint from FR 20’s right hand valance. Alan and Ade conducted a further hydraulic test on FR 20’s boiler on Wednesday after successfully making a new dome cover joint last week and Ade can be seen here working up some pressure. A formal test for the boiler surveyor has been booked for the 12th October.

Alan and Ade conducted a further hydraulic test on FR 20’s boiler on Wednesday after successfully making a new dome cover joint last week and Ade can be seen here working up some pressure. A formal test for the boiler surveyor has been booked for the 12th October. John Dixon finished finding or making the new studs for FR 20’s steam and blast pipes and had them fitted on Wednesday. He is seen here applying a die nut to one of the studs.

John Dixon finished finding or making the new studs for FR 20’s steam and blast pipes and had them fitted on Wednesday. He is seen here applying a die nut to one of the studs. Friday saw young Matthew join the gang having started a fabrication and welding course at college. He was quickly put to good use operating the hoist to lift one of the new engine springs into position for another test fit.

Friday saw young Matthew join the gang having started a fabrication and welding course at college. He was quickly put to good use operating the hoist to lift one of the new engine springs into position for another test fit. Keith has removed 5643’s valve and cylinder covers as he starts the valve and piston examination.

Keith has removed 5643’s valve and cylinder covers as he starts the valve and piston examination.

Finally, Fred was with us on Friday to continue his work cleaning up and painting the cab floor metalwork.

Finally, Fred was with us on Friday to continue his work cleaning up and painting the cab floor metalwork. Alan and Ade removed the dome cover from FR 20’s boiler with the assistance of Ribble Rail staff and the hi-ab. They then prepared a new joint before the dome cover was replaced and fastened down.

Alan and Ade removed the dome cover from FR 20’s boiler with the assistance of Ribble Rail staff and the hi-ab. They then prepared a new joint before the dome cover was replaced and fastened down. John Dixon continued and completed his work drilling out wasted or broken studs which secure the blastpipe and main steam pipe.

John Dixon continued and completed his work drilling out wasted or broken studs which secure the blastpipe and main steam pipe. Alan had picked up Caliban‘s valve spindles from IRS Surfacing Technologies at Burscough. They had been metal sprayed to counter corrosion and then ground back to size. From the finished job they looked brand new.

Alan had picked up Caliban‘s valve spindles from IRS Surfacing Technologies at Burscough. They had been metal sprayed to counter corrosion and then ground back to size. From the finished job they looked brand new. There has been more attention given to 5643 with Paul Balshaw cleaning up the rods.

There has been more attention given to 5643 with Paul Balshaw cleaning up the rods. Phil Bell focussed his attention beneath the cab floor, which has been removed to allow access.

Phil Bell focussed his attention beneath the cab floor, which has been removed to allow access. Fred came in on Friday to clean up some of the cab floor steelwork

Fred came in on Friday to clean up some of the cab floor steelwork Keith has given John Dixon the job of refurbishing a second-hand GWR cab seat and then creating another for Wootton Hall.

Keith has given John Dixon the job of refurbishing a second-hand GWR cab seat and then creating another for Wootton Hall. Lunchtimes these days are a little strange with members spacing themselves out either in the mess room or the shed. Here we see John Davis, Paul Newton and Phil Bell suitably socially distanced (no, we didn’t say spaced out!).

Lunchtimes these days are a little strange with members spacing themselves out either in the mess room or the shed. Here we see John Davis, Paul Newton and Phil Bell suitably socially distanced (no, we didn’t say spaced out!). The steam chest cover and tail rod bushes for the valve spindles have been re-fitted to FR 20, with Alan seen here at work on the matter.

The steam chest cover and tail rod bushes for the valve spindles have been re-fitted to FR 20, with Alan seen here at work on the matter. A number of steam pipe and blast pipe studs need to be replaced either through wastage or breakage. John Dixon tried to remove one of the blast pipe studs using some heat.

A number of steam pipe and blast pipe studs need to be replaced either through wastage or breakage. John Dixon tried to remove one of the blast pipe studs using some heat. Unfortunately, the heat treatment failed to make any difference so John is seen here (successfully) drilling out one of the broken studs.

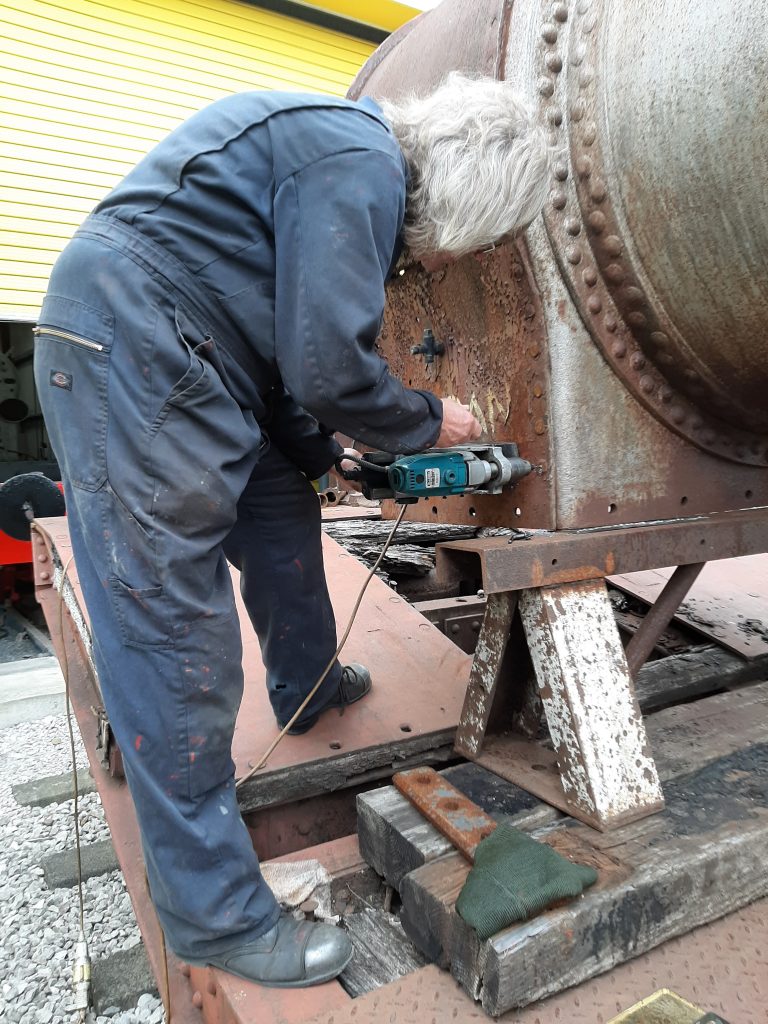

Unfortunately, the heat treatment failed to make any difference so John is seen here (successfully) drilling out one of the broken studs. The magnetic drill was much in demand last Wednesday when Ade also took the opportunity to start drilling out smokebox rivets on Caliban‘s boiler.

The magnetic drill was much in demand last Wednesday when Ade also took the opportunity to start drilling out smokebox rivets on Caliban‘s boiler. There has been further cleaning of 5643’s motion and frames.

There has been further cleaning of 5643’s motion and frames. 5643’s main brake shaft was removed by team Bell and Davis with a little help from Keith and the lifting table. It is a sizeable chunk of metal that has to be respected!

5643’s main brake shaft was removed by team Bell and Davis with a little help from Keith and the lifting table. It is a sizeable chunk of metal that has to be respected! Continuing Great Western news, Keith has been spending more time shaping the new injector delivery pipework for Wootton Hall.

Continuing Great Western news, Keith has been spending more time shaping the new injector delivery pipework for Wootton Hall.