Last Wednesday’s working party included an optional visit with RSR colleagues to the Commercial Vehicle Museum at Leyland, which was very much enjoyed by those who went. Some went off afterwards to review the learning points from the visit in one of the local hostelries (!) whilst others returned to Preston to continue their work on the FRT’s current projects.

A great deal of progress was made on both Wednesday and Friday with the thorough clean being given to Cumbria. Roger, Phil Bell, and John Dixon have concentrated their efforts on the frames, motion and brake rigging whilst John Davis worked on the wheels.

A great deal of progress was made on both Wednesday and Friday with the thorough clean being given to Cumbria. Roger, Phil Bell, and John Dixon have concentrated their efforts on the frames, motion and brake rigging whilst John Davis worked on the wheels.

Matt Jervis had successfully removed the ‘J’ pipe from the boiler which was subsequently machined by Bill Norcross.

Matt Jervis had successfully removed the ‘J’ pipe from the boiler which was subsequently machined by Bill Norcross.

Bob and Tim spent all their time on Friday (strictly limited number of tea breaks!) in their efforts to produce flat polished surfaces on both the regulator valve and ‘J’ pipe faces. Keith had kindly manufactured a flat steel plate to size with which to apply the carborundum paste although one or two high spots on the cast iron ‘J’ pipe needed some rather more aggressive attention! The task is still quite a way from completion and more work is planned for this next week.

Bob and Tim spent all their time on Friday (strictly limited number of tea breaks!) in their efforts to produce flat polished surfaces on both the regulator valve and ‘J’ pipe faces. Keith had kindly manufactured a flat steel plate to size with which to apply the carborundum paste although one or two high spots on the cast iron ‘J’ pipe needed some rather more aggressive attention! The task is still quite a way from completion and more work is planned for this next week.

Over at Embsay, Matt has successfully reamed and tapped out the three stay holes on the backhead of 5643’s firebox. On Saturday he then fitted and caulked up the new stays, which had conveniently arrived at Preston on Friday. A working party is planned for next Saturday during which it is hoped to conduct a washout of the boiler after which, if all is well, a warming fire will be lit in anticipation of a steam test next Sunday.

And as usual, there was further work this week on Fluff, with Howard making an additional visit on Friday to surprise us all!

A major project completed has been the installation of the new overhead safety wire system on road three of both the heated and unheated sections of the FRT shed. Wednesday, 20th February was spent on moving various pieces of equipment out of the way and taking delivery of a cherry picker and tower scaffold for use of the installers. That didn’t stop Adrian getting a few instructions on how to operate the cherry picker in order that it could be stowed away safely overnight.

A major project completed has been the installation of the new overhead safety wire system on road three of both the heated and unheated sections of the FRT shed. Wednesday, 20th February was spent on moving various pieces of equipment out of the way and taking delivery of a cherry picker and tower scaffold for use of the installers. That didn’t stop Adrian getting a few instructions on how to operate the cherry picker in order that it could be stowed away safely overnight. Fortunately, despite a short power outage, work progressed steadily during the day.

Fortunately, despite a short power outage, work progressed steadily during the day.  With the rolling stock now out of the way, the opportunity was also taken to undertake a thorough clean of the central section of the shed including the pit.

With the rolling stock now out of the way, the opportunity was also taken to undertake a thorough clean of the central section of the shed including the pit. Mike Rigg volunteered to try on one of the new harnesses and is seen here getting rigged up (geddit?!) with the assistance of Joe Jackson from Trad Safety Systems.

Mike Rigg volunteered to try on one of the new harnesses and is seen here getting rigged up (geddit?!) with the assistance of Joe Jackson from Trad Safety Systems.  A rear view of Mike shows the correct position, between the shoulder blades, for the metal loop to which the back strap should be attached. The installers finished a little later than planned, but all the rolling stock was back in the shed by 17.30 and Stanlow moved back home to the main running shed. A full operating instruction for the overhead safety wire system has been written and is available both in the mess room and in the harness storage drawer in the shed filing cabinet.

A rear view of Mike shows the correct position, between the shoulder blades, for the metal loop to which the back strap should be attached. The installers finished a little later than planned, but all the rolling stock was back in the shed by 17.30 and Stanlow moved back home to the main running shed. A full operating instruction for the overhead safety wire system has been written and is available both in the mess room and in the harness storage drawer in the shed filing cabinet. One side benefit from the upheaval in the shed was the opportunity to re-marshal the rolling stock so that Cumbria and FR 20 could be positioned over the pit to assist maintenance and repairs.

One side benefit from the upheaval in the shed was the opportunity to re-marshal the rolling stock so that Cumbria and FR 20 could be positioned over the pit to assist maintenance and repairs. Outside, Keith has been busy on repairs to the newly acquired tender tank for Wootton Hall and also in cutting up the original which, unfortunately, was well past being repaired. Alan has been loosening nuts with a view to removing FR 20’s valve chest cover and Adrian has been undercoating Caliban‘s frames. Work on Fluff progresses as well.

Outside, Keith has been busy on repairs to the newly acquired tender tank for Wootton Hall and also in cutting up the original which, unfortunately, was well past being repaired. Alan has been loosening nuts with a view to removing FR 20’s valve chest cover and Adrian has been undercoating Caliban‘s frames. Work on Fluff progresses as well. Ade is pictured here under the frames with the lance.

Ade is pictured here under the frames with the lance. Ade also received some driving instruction on Sentinel diesels and is seen here about Cumbria ready to do the shunt at the end of the washout.

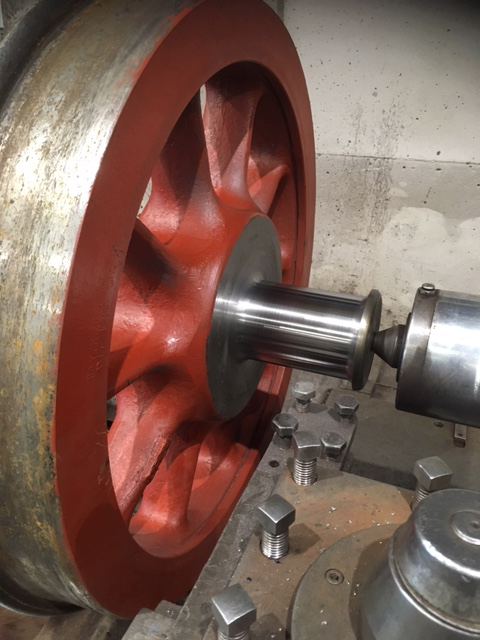

Ade also received some driving instruction on Sentinel diesels and is seen here about Cumbria ready to do the shunt at the end of the washout. Jeff Nixon at CMS Cepcor managed to find a slot on Thursday to undertake the skimming of the journals on FR 20’s tender wheelsets. He kindly sent us

Jeff Nixon at CMS Cepcor managed to find a slot on Thursday to undertake the skimming of the journals on FR 20’s tender wheelsets. He kindly sent us  After having gloss painted FR 20’s drag box and underside of the cab floor on Wednesday, John then bolted down the floor on Friday.

After having gloss painted FR 20’s drag box and underside of the cab floor on Wednesday, John then bolted down the floor on Friday. Roger kindly took on the task of cleaning Cumbria between the frames, making use of his head torch.

Roger kindly took on the task of cleaning Cumbria between the frames, making use of his head torch. Bob was missing from Friday’s working party (too busy consulting his lawyer regarding scurrilous accusations in a previous blog?!), however Fred spent his time cleaning out scale from the floor of Wootton Hall‘s tender tank.

Bob was missing from Friday’s working party (too busy consulting his lawyer regarding scurrilous accusations in a previous blog?!), however Fred spent his time cleaning out scale from the floor of Wootton Hall‘s tender tank. Bill Norcross has been busy machining the new underkeeps for Wootton Hall‘s tender axleboxes.

Bill Norcross has been busy machining the new underkeeps for Wootton Hall‘s tender axleboxes.

After Alan had inspected and cleaned the tubeholes on FR 20’s boiler, Friday afternoon was spent loading the new tubes into place. A supply chain was set up to hand over the tubes to Tim and John Dixon, who placed them into the boiler and applied suitable force where necessary. Meanwhile Alan spent his time in the firebox guiding the tubes into the correct hole and shouting suitable forms of encouragement to those loading the tubes. All in all, a very busy couple of hours!

After Alan had inspected and cleaned the tubeholes on FR 20’s boiler, Friday afternoon was spent loading the new tubes into place. A supply chain was set up to hand over the tubes to Tim and John Dixon, who placed them into the boiler and applied suitable force where necessary. Meanwhile Alan spent his time in the firebox guiding the tubes into the correct hole and shouting suitable forms of encouragement to those loading the tubes. All in all, a very busy couple of hours! Wednesday started early with members on site in good time to enable prompt loading of seven wheelsets when the low loader arrived. Just for the record there were three from Wootton Hall‘s tender, both Caliban‘s wheelsets and FR 20’s tender wheelsets. These are expected back sometime next month after attention to tyres and/or journals. Adrian is seen here with the fork lift.

Wednesday started early with members on site in good time to enable prompt loading of seven wheelsets when the low loader arrived. Just for the record there were three from Wootton Hall‘s tender, both Caliban‘s wheelsets and FR 20’s tender wheelsets. These are expected back sometime next month after attention to tyres and/or journals. Adrian is seen here with the fork lift. Martyn Soames straps the wheelsets to his rig.

Martyn Soames straps the wheelsets to his rig. Alan and John watch on here as Tim takes the drastic step of inspecting the instructions for the water pump in the hope that it might be coaxed into life.

Alan and John watch on here as Tim takes the drastic step of inspecting the instructions for the water pump in the hope that it might be coaxed into life. The rest of Wednesday was spent watching Crewe’s Class 47 D1924 being winched on to a massive trailer for trip back to its home depot. The loco had taken refuge at the RSR the previous Thursday after suffering a problem which prevented any longer distance movement by rail. We trust that D1924 will soon be back in good health.

The rest of Wednesday was spent watching Crewe’s Class 47 D1924 being winched on to a massive trailer for trip back to its home depot. The loco had taken refuge at the RSR the previous Thursday after suffering a problem which prevented any longer distance movement by rail. We trust that D1924 will soon be back in good health. On Friday John Dixon and Roger continued their work on FR 20’s drag box, attending to the securing holes on the footplate and applying a coat of undercoat.

On Friday John Dixon and Roger continued their work on FR 20’s drag box, attending to the securing holes on the footplate and applying a coat of undercoat. Matt Jervis made a start on removing Cumbria‘s regulator (borrowed from 3793) and ‘J’ pipe whilst Fred continued to clean Caliban‘s buffers. Paul Newton continued his work on the former L&NWR platform seat and John Davis and new volunteer Phil Bell attended to the removal of Fluff‘s rear cab sheet.

Matt Jervis made a start on removing Cumbria‘s regulator (borrowed from 3793) and ‘J’ pipe whilst Fred continued to clean Caliban‘s buffers. Paul Newton continued his work on the former L&NWR platform seat and John Davis and new volunteer Phil Bell attended to the removal of Fluff‘s rear cab sheet. There has been more progress on Wootton Hall with the arrival of new steel for the construction of the reverser – no, that round thing isn’t a log!

There has been more progress on Wootton Hall with the arrival of new steel for the construction of the reverser – no, that round thing isn’t a log! Keith has started the job of making up pipework for the injectors and is seen here with a newly cut corner stay for the recently purchased tender tank.

Keith has started the job of making up pipework for the injectors and is seen here with a newly cut corner stay for the recently purchased tender tank. We conclude with the sad task of recording the death last Thursday evening of former Live Steam band member Stuart Bennett. Stuart had, in the 1970s, been a member of popular South Lakeland folk group Bag ‘O Rags, which had entertained members on many occasions during those folk revival days. They were legendary occasions which brought many of our members together and the tales are still retold of merry nights out at such hostelries as the White Hart at Bouth and the Swan at Urswick. In 1999, after a period of time away from the folk music scene, Stuart accepted an invitation to join Live Steam and brought a new dimension to the band with his vocals, harmonies, guitar instrumentation and contributions to musical arrangements. Stuart clocked up over 140 gigs with the group, including the recording in 2001 of the CD Silver Jubilee, before reluctantly having to retire through ill health in 2008. We had many, many good times together and we send our sincere condolences to Stuart’s wife, Carol, and his family.

We conclude with the sad task of recording the death last Thursday evening of former Live Steam band member Stuart Bennett. Stuart had, in the 1970s, been a member of popular South Lakeland folk group Bag ‘O Rags, which had entertained members on many occasions during those folk revival days. They were legendary occasions which brought many of our members together and the tales are still retold of merry nights out at such hostelries as the White Hart at Bouth and the Swan at Urswick. In 1999, after a period of time away from the folk music scene, Stuart accepted an invitation to join Live Steam and brought a new dimension to the band with his vocals, harmonies, guitar instrumentation and contributions to musical arrangements. Stuart clocked up over 140 gigs with the group, including the recording in 2001 of the CD Silver Jubilee, before reluctantly having to retire through ill health in 2008. We had many, many good times together and we send our sincere condolences to Stuart’s wife, Carol, and his family. It was a very snowy Preston last Wednesday which probably explains why there was a delay to some of our members arriving. It was soon concluded that it was again too cold to undertake a washout on FR 20’s boiler.

It was a very snowy Preston last Wednesday which probably explains why there was a delay to some of our members arriving. It was soon concluded that it was again too cold to undertake a washout on FR 20’s boiler. There were still plenty of other jobs to undertake in the comparative warmth of the shed so Martin was put to good use after making that effort to come, and is seen here cleaning the accumulated dirt and oil from around the front of FR 20’s cylinders and valve chest.

There were still plenty of other jobs to undertake in the comparative warmth of the shed so Martin was put to good use after making that effort to come, and is seen here cleaning the accumulated dirt and oil from around the front of FR 20’s cylinders and valve chest. John Dixon test fitted a former for the future construction of a brick arch in FR 20’s firebox and Tim continued the task of cleaning and painting FR 20’s wheels.

John Dixon test fitted a former for the future construction of a brick arch in FR 20’s firebox and Tim continued the task of cleaning and painting FR 20’s wheels. Ade continued his laudable work on Caliban‘s frames by filling and sanding various indentations.

Ade continued his laudable work on Caliban‘s frames by filling and sanding various indentations. The cold weather put paid to any thoughts of undertaking a washout on FR 20’s boiler on Wednesday and so efforts were turned to removing Caliban‘s front buffers in readiness for the cylinders to be re-bored.

The cold weather put paid to any thoughts of undertaking a washout on FR 20’s boiler on Wednesday and so efforts were turned to removing Caliban‘s front buffers in readiness for the cylinders to be re-bored. The new tubes for FR 20’s boiler arrived late in the day and can be seen in this artistic photo taken by Ade of Alan inspecting the tubes viewed through the fork lift’s mechanism. (Suspect he just couldn’t be bothered to get off the fork lift! Ed.)

The new tubes for FR 20’s boiler arrived late in the day and can be seen in this artistic photo taken by Ade of Alan inspecting the tubes viewed through the fork lift’s mechanism. (Suspect he just couldn’t be bothered to get off the fork lift! Ed.) Cumbria‘s dome cover and dome lid were removed on Friday morning in readiness for the regulator and ‘J’ pipe to be removed for machining. John Dixon is seen here replacing one of the studs.

Cumbria‘s dome cover and dome lid were removed on Friday morning in readiness for the regulator and ‘J’ pipe to be removed for machining. John Dixon is seen here replacing one of the studs. Fred spent much of the day finishing the cleaning up of FR 20’s tender wheels…

Fred spent much of the day finishing the cleaning up of FR 20’s tender wheels… … then John Dixon applied a coat of red oxide paint.

… then John Dixon applied a coat of red oxide paint. Roger continued Phil’s efforts at cleaning FR 20’s brasswork and can be seen here busy at his work.

Roger continued Phil’s efforts at cleaning FR 20’s brasswork and can be seen here busy at his work. Keith has been working on the new keeps for Wootton Hall’s tender, and is seen here fitting one to one of the axleboxes.

Keith has been working on the new keeps for Wootton Hall’s tender, and is seen here fitting one to one of the axleboxes. Firstly, as predicted, Cumbria arrived back at Preston last Monday and was tucked into the top of road three in the FRT shed ready for attention.

Firstly, as predicted, Cumbria arrived back at Preston last Monday and was tucked into the top of road three in the FRT shed ready for attention. Work has continued on FR 20 with the first of the Indian Red gloss paint being applied to the engine’s wheelsets. This is literally a rolling programme as the engine will need to be rolled forwards or backwards for all areas of the wheels to be so decorated! All the copper pipework has been cleaned up ready for annealing to take place and further cleaning and polishing work has been carried out on the brass that fits to the front and back of the firebox. The steam cleaning of the tender wheelsets has been completed and they have been given a further hand clean in readiness for paint to be applied. Finally, new tubes have been ordered and a cheque despatched; the tubes should appear in the next couple of weeks. Meanwhile, with the all the old tubes now removed, a washout is planned for Wednesday, subject to a shunt being arranged and the pressure washer playing ball. With the formal NDT report now received, it should then be time to call in the boiler surveyor.

Work has continued on FR 20 with the first of the Indian Red gloss paint being applied to the engine’s wheelsets. This is literally a rolling programme as the engine will need to be rolled forwards or backwards for all areas of the wheels to be so decorated! All the copper pipework has been cleaned up ready for annealing to take place and further cleaning and polishing work has been carried out on the brass that fits to the front and back of the firebox. The steam cleaning of the tender wheelsets has been completed and they have been given a further hand clean in readiness for paint to be applied. Finally, new tubes have been ordered and a cheque despatched; the tubes should appear in the next couple of weeks. Meanwhile, with the all the old tubes now removed, a washout is planned for Wednesday, subject to a shunt being arranged and the pressure washer playing ball. With the formal NDT report now received, it should then be time to call in the boiler surveyor. Progress has also been made on Wootton Hall where brass edging to the cab side can now be seen in place. A start has also been made on bringing together the components for the brake gear so that it can be assembled on the tender.

Progress has also been made on Wootton Hall where brass edging to the cab side can now be seen in place. A start has also been made on bringing together the components for the brake gear so that it can be assembled on the tender. We start with the news that a milestone in the restoration of the FRT’s ‘Hall’ class 4-6-0 locomotive No. 4979 Wootton Hall was reached on Thursday when the riveting gang fitted the last rivet to the re-built tender frames. The front of the tender frames had been severely wasted by years of water and coal dust which had cascaded down from the cab floor. As followers of this blog will know, the riveting team of Matt Jervis, Keith Brewer, John Dixon and Chris Rycroft have been meeting regularly on Thursdays over the last few months and have been responsible for completing the fitting of several hundred rivets which have locked together the new steelwork with the old. The final day saw 30 rivets fitted, which is quite an effort! Well done to all!

We start with the news that a milestone in the restoration of the FRT’s ‘Hall’ class 4-6-0 locomotive No. 4979 Wootton Hall was reached on Thursday when the riveting gang fitted the last rivet to the re-built tender frames. The front of the tender frames had been severely wasted by years of water and coal dust which had cascaded down from the cab floor. As followers of this blog will know, the riveting team of Matt Jervis, Keith Brewer, John Dixon and Chris Rycroft have been meeting regularly on Thursdays over the last few months and have been responsible for completing the fitting of several hundred rivets which have locked together the new steelwork with the old. The final day saw 30 rivets fitted, which is quite an effort! Well done to all! John is seen preparing the gas torch to heat up the rivets.

John is seen preparing the gas torch to heat up the rivets. Keith is pictured holding the final hot rivet in place.

Keith is pictured holding the final hot rivet in place. And Matt Jervis applies the force to finish the job.

And Matt Jervis applies the force to finish the job. Staying with the Hall’s tender, and Alan Middleton is seen on Wednesday with the newly arrived second hand 4,000 gallon Collett tender tank recently arrived from Tyseley.

Staying with the Hall’s tender, and Alan Middleton is seen on Wednesday with the newly arrived second hand 4,000 gallon Collett tender tank recently arrived from Tyseley. As you will see here, it didn’t take long for Keith to set to with a cutting disc to remove the corroded shoveling plate. This will also enable scale to be removed from the tender tank.

As you will see here, it didn’t take long for Keith to set to with a cutting disc to remove the corroded shoveling plate. This will also enable scale to be removed from the tender tank. Onto other projects, and the axleboxes have been removed from FR 20’s tender wheelsets and cleaned. The wheelsets have received some attention from scrapers to remove twenty years of grime and the first set is seen here being steam cleaned by Matt Bedford.

Onto other projects, and the axleboxes have been removed from FR 20’s tender wheelsets and cleaned. The wheelsets have received some attention from scrapers to remove twenty years of grime and the first set is seen here being steam cleaned by Matt Bedford. Andy Booth has completed the removal of the tubes from FR 20’s boiler and they were cut in half by John Davis before being placed in the scrap metal skip.

Andy Booth has completed the removal of the tubes from FR 20’s boiler and they were cut in half by John Davis before being placed in the scrap metal skip. There was a visit to Embsay on Saturday by Keith, Fred and Mike. Fred and Mike cleaned below the running plate on 5643 whilst Keith attacked the inside motion. Both 5643 and Cumbria were drawn outside the shed to allow the water to be drained from the boilers and for Cumbria’s spare springs to be loaded.

There was a visit to Embsay on Saturday by Keith, Fred and Mike. Fred and Mike cleaned below the running plate on 5643 whilst Keith attacked the inside motion. Both 5643 and Cumbria were drawn outside the shed to allow the water to be drained from the boilers and for Cumbria’s spare springs to be loaded.  There was then time to polish up the bright work.

There was then time to polish up the bright work. This marked the end of regular loco-hauled services along the Cumbrian Coast. The Class 37 diagrams are now covered by Class 156 diesel multiple units, themselves now around thirty years old.

This marked the end of regular loco-hauled services along the Cumbrian Coast. The Class 37 diagrams are now covered by Class 156 diesel multiple units, themselves now around thirty years old. Work has continued apace on the overhaul of FR 20, with Alan seen here prising off the front right hand cylinder cover. Both covers were removed with assistance from Ade and, at first sight, it looks as if new pistons rings will be required. Tim has since located the spare set that was ordered over twenty years ago.

Work has continued apace on the overhaul of FR 20, with Alan seen here prising off the front right hand cylinder cover. Both covers were removed with assistance from Ade and, at first sight, it looks as if new pistons rings will be required. Tim has since located the spare set that was ordered over twenty years ago. Cleaning and painting of the engine’s wheels has also continued with a primer/undercoat of red oxide being visible here.

Cleaning and painting of the engine’s wheels has also continued with a primer/undercoat of red oxide being visible here. John Dixon has been cleaning up the toolbox that is usually located on the running board to the right of the smoke box.

John Dixon has been cleaning up the toolbox that is usually located on the running board to the right of the smoke box. The decision was taken to lift the tender to get the axle journals skimmed and polished as these had given some problems in times past. Ade is seen here moving the tender to the unloading road after a massive shunt on the 2nd January. Well done Ade!

The decision was taken to lift the tender to get the axle journals skimmed and polished as these had given some problems in times past. Ade is seen here moving the tender to the unloading road after a massive shunt on the 2nd January. Well done Ade! Work has also continued on cleaning up Fluff‘s frames and bodywork over the Christmas period and John Davis is seen here at work with Mike Rigg.

Work has also continued on cleaning up Fluff‘s frames and bodywork over the Christmas period and John Davis is seen here at work with Mike Rigg. Keith has, as ever, been working on Wootton Hall and the left hand ‘Collett style’ cab side is seen here mounted temporarily.

Keith has, as ever, been working on Wootton Hall and the left hand ‘Collett style’ cab side is seen here mounted temporarily. After eight days of playing Christmas songs on the RSR’s Santa Specials before Christmas you would have thought that Alan and Tim would have wanted a rest, but they are seen here with George and Pete performing a successful Live Steam gig at the Engine Inn at Cark-in-Cartmel on New Year’s Eve.

After eight days of playing Christmas songs on the RSR’s Santa Specials before Christmas you would have thought that Alan and Tim would have wanted a rest, but they are seen here with George and Pete performing a successful Live Steam gig at the Engine Inn at Cark-in-Cartmel on New Year’s Eve. Friday, 4th January brought the good news that FR 20’s boiler and the three Hall tender wheelsets had passed Jim Kennedy’s NDT examination. Jim is seen here at work on the boiler.

Friday, 4th January brought the good news that FR 20’s boiler and the three Hall tender wheelsets had passed Jim Kennedy’s NDT examination. Jim is seen here at work on the boiler. The axleboxes were transferred over to the FRT shed so that the components can be cleaned up. This was an opportunity to use the previously untested parts washer that had been generously donated to the FRT some while ago. After studious reading of the instructions (that’s unusual!) Keith Brewer watches on as John Dixon cleans the axlebox covers.

The axleboxes were transferred over to the FRT shed so that the components can be cleaned up. This was an opportunity to use the previously untested parts washer that had been generously donated to the FRT some while ago. After studious reading of the instructions (that’s unusual!) Keith Brewer watches on as John Dixon cleans the axlebox covers. Late afternoon the newly purchased Collett tender tank arrived from Tyseley.

Late afternoon the newly purchased Collett tender tank arrived from Tyseley. After some time manoeuvring of the low loader and crane into position, the tank was successfully lifted on to pallets alongside the FRT shed. The photo below shows a winter’s evening scene at Preston as preparations are made for the lift.

After some time manoeuvring of the low loader and crane into position, the tank was successfully lifted on to pallets alongside the FRT shed. The photo below shows a winter’s evening scene at Preston as preparations are made for the lift. Keith is seen here opening another early birthday present on Wednesday when a set of newly cast axlebox underkeeps and brasses appeared in a delivery from the Severn Valley Railway.

Keith is seen here opening another early birthday present on Wednesday when a set of newly cast axlebox underkeeps and brasses appeared in a delivery from the Severn Valley Railway.  The axlebox underkeeps are indeed fine castings with no signs of corrective fettling, as can be seen here.

The axlebox underkeeps are indeed fine castings with no signs of corrective fettling, as can be seen here. On the departure side, Adrian is seen here placing on to the delivery lorry a set of six springs from Wootton Hall‘s tender which are to be overhauled after over fifty years out of use. Two spare springs are to be manufactured at the same time.

On the departure side, Adrian is seen here placing on to the delivery lorry a set of six springs from Wootton Hall‘s tender which are to be overhauled after over fifty years out of use. Two spare springs are to be manufactured at the same time. And talking of Wootton Hall, Keith is seen here temporarily fitting the right hand cab side in order to take measurements for boiler cladding and other fittings.

And talking of Wootton Hall, Keith is seen here temporarily fitting the right hand cab side in order to take measurements for boiler cladding and other fittings. Another view here with the cab side number plate fitted completely alters the appearance of the loco and shows signs of things to come!

Another view here with the cab side number plate fitted completely alters the appearance of the loco and shows signs of things to come! The main job on Wednesday was to jack up FR 20’s boiler to allow easier access from under the firebox. The front of the boiler is now positioned on steel stands.

The main job on Wednesday was to jack up FR 20’s boiler to allow easier access from under the firebox. The front of the boiler is now positioned on steel stands.