First of all we can report that the Annual General Meeting successfully took place last Tuesday evening with the participants able to attend from the comfort of their homes using Zoom technology. The essential business was conducted without fuss in a record time of 20 minutes and the draft minutes produced before bedtime! Thanks go to all of you who attended.

Alan and Ade removed the dome cover from FR 20’s boiler with the assistance of Ribble Rail staff and the hi-ab. They then prepared a new joint before the dome cover was replaced and fastened down.

Alan and Ade removed the dome cover from FR 20’s boiler with the assistance of Ribble Rail staff and the hi-ab. They then prepared a new joint before the dome cover was replaced and fastened down.

John Dixon continued and completed his work drilling out wasted or broken studs which secure the blastpipe and main steam pipe.

John Dixon continued and completed his work drilling out wasted or broken studs which secure the blastpipe and main steam pipe.

Alan had picked up Caliban‘s valve spindles from IRS Surfacing Technologies at Burscough. They had been metal sprayed to counter corrosion and then ground back to size. From the finished job they looked brand new.

Alan had picked up Caliban‘s valve spindles from IRS Surfacing Technologies at Burscough. They had been metal sprayed to counter corrosion and then ground back to size. From the finished job they looked brand new.

There has been more attention given to 5643 with Paul Balshaw cleaning up the rods.

There has been more attention given to 5643 with Paul Balshaw cleaning up the rods.

Phil Bell focussed his attention beneath the cab floor, which has been removed to allow access.

Phil Bell focussed his attention beneath the cab floor, which has been removed to allow access.

Fred came in on Friday to clean up some of the cab floor steelwork

Fred came in on Friday to clean up some of the cab floor steelwork

Keith has given John Dixon the job of refurbishing a second-hand GWR cab seat and then creating another for Wootton Hall.

Keith has given John Dixon the job of refurbishing a second-hand GWR cab seat and then creating another for Wootton Hall.

Lunchtimes these days are a little strange with members spacing themselves out either in the mess room or the shed. Here we see John Davis, Paul Newton and Phil Bell suitably socially distanced (no, we didn’t say spaced out!).

Lunchtimes these days are a little strange with members spacing themselves out either in the mess room or the shed. Here we see John Davis, Paul Newton and Phil Bell suitably socially distanced (no, we didn’t say spaced out!).

The steam chest cover and tail rod bushes for the valve spindles have been re-fitted to FR 20, with Alan seen here at work on the matter.

The steam chest cover and tail rod bushes for the valve spindles have been re-fitted to FR 20, with Alan seen here at work on the matter. A number of steam pipe and blast pipe studs need to be replaced either through wastage or breakage. John Dixon tried to remove one of the blast pipe studs using some heat.

A number of steam pipe and blast pipe studs need to be replaced either through wastage or breakage. John Dixon tried to remove one of the blast pipe studs using some heat. Unfortunately, the heat treatment failed to make any difference so John is seen here (successfully) drilling out one of the broken studs.

Unfortunately, the heat treatment failed to make any difference so John is seen here (successfully) drilling out one of the broken studs. The magnetic drill was much in demand last Wednesday when Ade also took the opportunity to start drilling out smokebox rivets on Caliban‘s boiler.

The magnetic drill was much in demand last Wednesday when Ade also took the opportunity to start drilling out smokebox rivets on Caliban‘s boiler. There has been further cleaning of 5643’s motion and frames.

There has been further cleaning of 5643’s motion and frames. 5643’s main brake shaft was removed by team Bell and Davis with a little help from Keith and the lifting table. It is a sizeable chunk of metal that has to be respected!

5643’s main brake shaft was removed by team Bell and Davis with a little help from Keith and the lifting table. It is a sizeable chunk of metal that has to be respected! Continuing Great Western news, Keith has been spending more time shaping the new injector delivery pipework for Wootton Hall.

Continuing Great Western news, Keith has been spending more time shaping the new injector delivery pipework for Wootton Hall. Work on 5643 has continued at Preston with Keith dismantling more brake gear under a much cleaner locomotive after all the recent work between the frames.

Work on 5643 has continued at Preston with Keith dismantling more brake gear under a much cleaner locomotive after all the recent work between the frames. Phil has then been further dismantling items and cleaning them.

Phil has then been further dismantling items and cleaning them. Fred and John Davis had another cleaning session on the right hand frames on Friday and are seen here dutifully observing the yellow distancing markers on the floor.

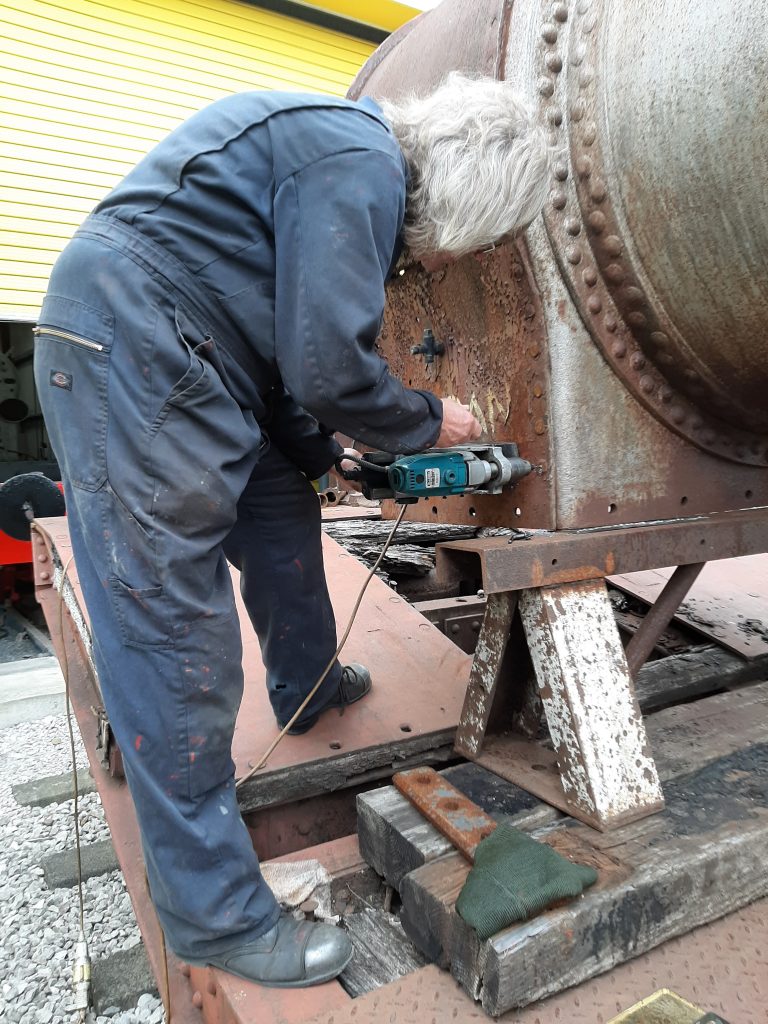

Fred and John Davis had another cleaning session on the right hand frames on Friday and are seen here dutifully observing the yellow distancing markers on the floor. Work has also continued on FR 20 where the removal of all the spring hangers for machining has allowed further cleaning and painting of the frames to take place. John Dixon is seen in a most inelegant pose repairing the blastpipe retaining studs – we suspect he won’t be thanking the photographer!

Work has also continued on FR 20 where the removal of all the spring hangers for machining has allowed further cleaning and painting of the frames to take place. John Dixon is seen in a most inelegant pose repairing the blastpipe retaining studs – we suspect he won’t be thanking the photographer! John appeared after the Covid lockdown with some homework, a couple of lamp bracket converters for FR 20 for such things as DO NOT MOVE signs.

John appeared after the Covid lockdown with some homework, a couple of lamp bracket converters for FR 20 for such things as DO NOT MOVE signs. Keith has fitted the first piece of firebox cladding on Wootton Hall, carefully allowing for the attachment of the four cone ejector.

Keith has fitted the first piece of firebox cladding on Wootton Hall, carefully allowing for the attachment of the four cone ejector. Finally, Ed appeared the previous Wednesday and did a splendid job in putting the nearby garden to rights after it had suffered some lockdown dereliction.

Finally, Ed appeared the previous Wednesday and did a splendid job in putting the nearby garden to rights after it had suffered some lockdown dereliction. The new springs for FR 20 are still in the course of being fitted, with John Dixon seen here positioning one on to the frames. Further examination of the spring hangers suggested that there has been a small long standing mis-alignment between the spring hangers and the centre pins which support the springs. All the spring hangers have now been removed to enable them to be machined and, hopefully, a perfect fit obtained.

The new springs for FR 20 are still in the course of being fitted, with John Dixon seen here positioning one on to the frames. Further examination of the spring hangers suggested that there has been a small long standing mis-alignment between the spring hangers and the centre pins which support the springs. All the spring hangers have now been removed to enable them to be machined and, hopefully, a perfect fit obtained. 5643 was moved on to the pit outside the RSR running shed on the 7th August which enabled the ashpan to be given a thorough clean. John Davis is seen at the bottom of the cab steps feeding a hose pipe into the cab.

5643 was moved on to the pit outside the RSR running shed on the 7th August which enabled the ashpan to be given a thorough clean. John Davis is seen at the bottom of the cab steps feeding a hose pipe into the cab. Keith’s arms look suitably grubby after the ashpan cleaning.

Keith’s arms look suitably grubby after the ashpan cleaning. Once this had been done, Phil went underneath to undertake some pressure washing between the frames.

Once this had been done, Phil went underneath to undertake some pressure washing between the frames. Last Wednesday Keith was in the process of replacing the heavily corroded driver’s side cab step plate.

Last Wednesday Keith was in the process of replacing the heavily corroded driver’s side cab step plate. Wootton Hall is now sporting a brand new right hand brass cab window frame which has recently been cast.

Wootton Hall is now sporting a brand new right hand brass cab window frame which has recently been cast. Ade fetched around the new engine springs for FR 20 from the RSR’s plant room where they had been in store since delivery during lockdown. Ade caught Tim ‘springing’ into action with a sack truck.

Ade fetched around the new engine springs for FR 20 from the RSR’s plant room where they had been in store since delivery during lockdown. Ade caught Tim ‘springing’ into action with a sack truck. After which Ade lifted one of the new springs into position for a test fit.

After which Ade lifted one of the new springs into position for a test fit. Elsewhere on FR 20, John has been upgrading some of the tender brake pipework.

Elsewhere on FR 20, John has been upgrading some of the tender brake pipework. Work has also continued with the cleaning of 5643 and Phil is seen here working in the pit.

Work has also continued with the cleaning of 5643 and Phil is seen here working in the pit. Keith is also seen here surveying 5643 for future work from the pit.

Keith is also seen here surveying 5643 for future work from the pit. He is seen here awaiting final adjustment to his harness….

He is seen here awaiting final adjustment to his harness…. … and then atop 5643 cleaning its chimney.

… and then atop 5643 cleaning its chimney. Over in the running shed some of the FRT’s team have been installing refurbished seating on the RSR’s TSO no. 5036 and doing a very good job by the looks of it.

Over in the running shed some of the FRT’s team have been installing refurbished seating on the RSR’s TSO no. 5036 and doing a very good job by the looks of it. Fred tackles the smoke box…

Fred tackles the smoke box… John Davis the left hand side…

John Davis the left hand side… and Phil the right hand guard iron.

and Phil the right hand guard iron. Finally, we were also pleased to note the resumption of passenger services at the Embsay & Bolton Abbey Steam Railway on Saturday. A special effort was made to clean the FRT’s ‘Austerity’ 0-6-0ST Cumbria for the occasion and the gleaming loco is seen here with a passenger train, courtesy of a photo from the Embsay Loco Dept Facebook page. Well done to all concerned for a great effort!

Finally, we were also pleased to note the resumption of passenger services at the Embsay & Bolton Abbey Steam Railway on Saturday. A special effort was made to clean the FRT’s ‘Austerity’ 0-6-0ST Cumbria for the occasion and the gleaming loco is seen here with a passenger train, courtesy of a photo from the Embsay Loco Dept Facebook page. Well done to all concerned for a great effort! Yet another blog, this time to let you know that 5643 arrived back at Preston this afternoon and is now tucked up in the FRT shed.

Yet another blog, this time to let you know that 5643 arrived back at Preston this afternoon and is now tucked up in the FRT shed.  Thanks to Adrian and Keith who oversaw the unloading and shunt for us. This is how the reorganised shed now looks:

Thanks to Adrian and Keith who oversaw the unloading and shunt for us. This is how the reorganised shed now looks:

Phil joined us to hoover the RSR workshop and plant room.

Phil joined us to hoover the RSR workshop and plant room. Tim, working with John Dixon, painted a further eighty marking lines at 2 metres distance so completing the bulk of this work – or so Tim’s knees hope!

Tim, working with John Dixon, painted a further eighty marking lines at 2 metres distance so completing the bulk of this work – or so Tim’s knees hope! We also had the welcome sight of Alan on Wednesday for the first time after his Covid-19 illness, also sporting a lockdown haircut. He has taken the copy for the latest edition of The Iron Horse to the printers so hopefully it should not be too long before one lands through members’ letterboxes.

We also had the welcome sight of Alan on Wednesday for the first time after his Covid-19 illness, also sporting a lockdown haircut. He has taken the copy for the latest edition of The Iron Horse to the printers so hopefully it should not be too long before one lands through members’ letterboxes. Back to the good news, Ade, John Dixon, Tim and Keith re-united at Preston last Wednesday after a gap of three and a half months.

Back to the good news, Ade, John Dixon, Tim and Keith re-united at Preston last Wednesday after a gap of three and a half months.  Tim had brought down with him various boxes containing PPE, hand gel, adhesive tape and floor paint. The plan was to lay markers at 2 metres distance in both the RSR and FRT sheds. It was decided to practice with the FRT shed where Ade (sporting a 100 day isolation hair style) hoovered the floor.

Tim had brought down with him various boxes containing PPE, hand gel, adhesive tape and floor paint. The plan was to lay markers at 2 metres distance in both the RSR and FRT sheds. It was decided to practice with the FRT shed where Ade (sporting a 100 day isolation hair style) hoovered the floor.

Once the time consuming option of masking tape had been ditched, John made up a wooden stencil to enable Tim to apply some yellow marking paint, which appeared to do the trick.

Once the time consuming option of masking tape had been ditched, John made up a wooden stencil to enable Tim to apply some yellow marking paint, which appeared to do the trick.

In the meantime, we are pleased to be able to inform you that you can now buy your very own (rather smaller) 5643! Sonic Models are producing some N gauge versions of the 56xx, including our very own 5643, which are due to be available from the autumn. 5643 will be depicted as is, in pristine lined green livery with the later BR crest (the weathered version with the later crest depicts 6681; there are also other GWR and BR livery options). These are limited edition models which are being marketed exclusively by the well-known model retailers

In the meantime, we are pleased to be able to inform you that you can now buy your very own (rather smaller) 5643! Sonic Models are producing some N gauge versions of the 56xx, including our very own 5643, which are due to be available from the autumn. 5643 will be depicted as is, in pristine lined green livery with the later BR crest (the weathered version with the later crest depicts 6681; there are also other GWR and BR livery options). These are limited edition models which are being marketed exclusively by the well-known model retailers  Whilst on the subject of retailing, Alison tells us that she can now supply black FRT customised polo and sweat shirts at £11.50 and £15.00 respectively each to members plus P&P – large and extra large sizes only at the moment.

Whilst on the subject of retailing, Alison tells us that she can now supply black FRT customised polo and sweat shirts at £11.50 and £15.00 respectively each to members plus P&P – large and extra large sizes only at the moment.