A quick Bank Holiday update before settling down on the sofa for the last time with Demelza this evening – last edition of Poldark for those that don’t watch it.

Andy Booth has completed the expansion of the tubes in the FR 20’s boiler and has been beading them over in the firebox. He will return to complete the job early in September. Meanwhile, Fred has started the job of giving the boiler a coat of paint.

Andy Booth has completed the expansion of the tubes in the FR 20’s boiler and has been beading them over in the firebox. He will return to complete the job early in September. Meanwhile, Fred has started the job of giving the boiler a coat of paint.

FR 20’s brake rigging has received a couple of coats of paint and it is planned to reassemble the tender axleboxes shortly ready for the tender to be placed back on its wheels.  Roger has again been on his knees painting the boiler cladding or, as we are assured by John Dixon the correct term is, clothing.

Roger has again been on his knees painting the boiler cladding or, as we are assured by John Dixon the correct term is, clothing.

Alan Vipond has been machining Caliban‘s newly white metalled bearings ready for them to be scraped in.

Alan Vipond has been machining Caliban‘s newly white metalled bearings ready for them to be scraped in.

Ade, who spent most of last Wednesday shunting carriages, has fitted one of the spring hangers with one of the newly manufactured pins.

Ade, who spent most of last Wednesday shunting carriages, has fitted one of the spring hangers with one of the newly manufactured pins.

John Dixon has been making a new bench for a pipe bending vice.

John Dixon has been making a new bench for a pipe bending vice.

And Phil Bell has continued his work on Fluff‘s cab platework.

And Phil Bell has continued his work on Fluff‘s cab platework.

Finally, over at Embsay a hydraulic test has been successfully completed on Cumbria to test the ‘J’ pipe and fireman’s side injector delivery pipe. A boiler washout was being carried out this last weekend in preparation for the loco’s boiler survey.

We arrived at Preston on Wednesday to hear the distant sound of a steam chime whistle and later found out that it was none other than 70000 Britannia on a northbound run through Preston to Carlisle. Just for the record, here is a photo of the loco heading back south through Lancaster at speed with The Lakelander just after 5 pm.

We arrived at Preston on Wednesday to hear the distant sound of a steam chime whistle and later found out that it was none other than 70000 Britannia on a northbound run through Preston to Carlisle. Just for the record, here is a photo of the loco heading back south through Lancaster at speed with The Lakelander just after 5 pm. Tim and John Dixon virtually completed the painting of FR 20’s frames, motion and wheels on Wednesday. John is seen here painting some of the motion.

Tim and John Dixon virtually completed the painting of FR 20’s frames, motion and wheels on Wednesday. John is seen here painting some of the motion. The fresh gloss paint on the frames and motion now gives it a smart appearance.

The fresh gloss paint on the frames and motion now gives it a smart appearance. Finally a painted and lined out wheel.

Finally a painted and lined out wheel. Roger came in on Friday and started the task of cleaning and painting the internal surface of the boiler cladding sheets.

Roger came in on Friday and started the task of cleaning and painting the internal surface of the boiler cladding sheets. John has been preparing some new wood to be inserted on top of the front buffer beam where previous area of oak had perished.

John has been preparing some new wood to be inserted on top of the front buffer beam where previous area of oak had perished. Fred has continued to work on cleaning up the smokebox and we have a rare photo here of him having a ten minute breather.

Fred has continued to work on cleaning up the smokebox and we have a rare photo here of him having a ten minute breather. Work continues apace on Fluff with John Davis drilling holes in the newly inserted steel stretcher plate between the frames.

Work continues apace on Fluff with John Davis drilling holes in the newly inserted steel stretcher plate between the frames. Phil Bell has continued the task of drilling holes in one of the new cab sides.

Phil Bell has continued the task of drilling holes in one of the new cab sides. Ade has been testing the fit of the first of his newly fabricated axlebox covers for Caliban.

Ade has been testing the fit of the first of his newly fabricated axlebox covers for Caliban.  First of all he hoisted a test axlebox into position before heading off to the bench with a file to start the process of modification!

First of all he hoisted a test axlebox into position before heading off to the bench with a file to start the process of modification! We are glad to be able to report that Bill Norcross is back from sick leave and he is seen here setting up to drill some holes in a brass flange for Wootton Hall.

We are glad to be able to report that Bill Norcross is back from sick leave and he is seen here setting up to drill some holes in a brass flange for Wootton Hall. Paul Newton came in on Friday to continue his work on the L&NWR seat from Preston station.

Paul Newton came in on Friday to continue his work on the L&NWR seat from Preston station. Work on FR 20 has this last week focused on completing the painting of the engine frames and wheels. Lining out the wheels can be an awkward job and Ade caught Tim trying to make himself comfortable on the floor before finishing off the right rear wheel – you can never find a pillow when you need one!! Meanwhile Alan has finished scraping in the white metalled tender bearings.

Work on FR 20 has this last week focused on completing the painting of the engine frames and wheels. Lining out the wheels can be an awkward job and Ade caught Tim trying to make himself comfortable on the floor before finishing off the right rear wheel – you can never find a pillow when you need one!! Meanwhile Alan has finished scraping in the white metalled tender bearings. There has been continuing good progress with Fluff as various components are freed off and prepared for re-fitting. Paul Balshaw has primed some more areas between the frames whilst Phil Bell has been preparing new cab sheets (seen here in store) as well as re-working an existing door sheet that can be re-used.

There has been continuing good progress with Fluff as various components are freed off and prepared for re-fitting. Paul Balshaw has primed some more areas between the frames whilst Phil Bell has been preparing new cab sheets (seen here in store) as well as re-working an existing door sheet that can be re-used.

Jimmy Dutton has completed the white metalling of the bearings which await machining once Alan has returned from sunning himself in the south of England.

Jimmy Dutton has completed the white metalling of the bearings which await machining once Alan has returned from sunning himself in the south of England. Keith is seen here modelling the new welding mask complete with air blower.

Keith is seen here modelling the new welding mask complete with air blower. Alan, John and Tim spent the latter part of Wednesday assembling the new mobile fume extractor. Delivery was certainly very prompt but, unlike a car which you expect to be able to drive away from a salesroom without having to fit the wheels, the same cannot be said for the supposedly mobile fume extractor which turned up with quite a number of subsidiary cardboard boxes containing wheels, tube, extending mechanism, nuts bolts and sealing rings plus (just to confuse) a few bits and pieces that you didn’t actually need. Added to that were various meaty booklets in a wide range of languages with complex diagrams explaining how your A level rated Meccano set should be constructed. Of particular note, there was an alarming warning sign illustrated with a set of teeth that indicated that you had to be careful when releasing the tensioned extending mechanism from tie wraps to prevent yourself receiving a blow in the mouth!

Alan, John and Tim spent the latter part of Wednesday assembling the new mobile fume extractor. Delivery was certainly very prompt but, unlike a car which you expect to be able to drive away from a salesroom without having to fit the wheels, the same cannot be said for the supposedly mobile fume extractor which turned up with quite a number of subsidiary cardboard boxes containing wheels, tube, extending mechanism, nuts bolts and sealing rings plus (just to confuse) a few bits and pieces that you didn’t actually need. Added to that were various meaty booklets in a wide range of languages with complex diagrams explaining how your A level rated Meccano set should be constructed. Of particular note, there was an alarming warning sign illustrated with a set of teeth that indicated that you had to be careful when releasing the tensioned extending mechanism from tie wraps to prevent yourself receiving a blow in the mouth!  We are pleased to be able to report that the extractor was successfully assembled without damage to either the equipment or the volunteers and that Nellie (with the extendable trunk) was tested without managing to inhale any loose wigs…

We are pleased to be able to report that the extractor was successfully assembled without damage to either the equipment or the volunteers and that Nellie (with the extendable trunk) was tested without managing to inhale any loose wigs… The overhaul of FR 20 continues to make steady progress with Alan working on the last of the newly white metalled bearings for the tender.

The overhaul of FR 20 continues to make steady progress with Alan working on the last of the newly white metalled bearings for the tender. John Dixon and Tim have been busy putting gloss Indian Red paint on the frames, and undertaking further cleaning and painting of the wheels now that the engine has been moved a few yards further forward.

John Dixon and Tim have been busy putting gloss Indian Red paint on the frames, and undertaking further cleaning and painting of the wheels now that the engine has been moved a few yards further forward. Work has also continued on Fluff where components are now being re-fitted. Phil Bell is seen here giving the loco a well aimed hammering under the watchful gaze of Alan, Howard and Paul Balshaw.

Work has also continued on Fluff where components are now being re-fitted. Phil Bell is seen here giving the loco a well aimed hammering under the watchful gaze of Alan, Howard and Paul Balshaw. A jig has been made up to mount Fluff‘s engine which is seen here being lowered into place with assistance from Jim Hanmer and Alan Preston.

A jig has been made up to mount Fluff‘s engine which is seen here being lowered into place with assistance from Jim Hanmer and Alan Preston. It was Howard’s birthday on Wednesday and he is seen blowing out the candles on his cake, made by Alison.

It was Howard’s birthday on Wednesday and he is seen blowing out the candles on his cake, made by Alison. Ade enjoyed sampling one of the dozen trifles that Howard brought along to celebrate the occasion.

Ade enjoyed sampling one of the dozen trifles that Howard brought along to celebrate the occasion. Alison thought that it was her birthday as well when she saw the new roundabout being installed in the children’s playground.

Alison thought that it was her birthday as well when she saw the new roundabout being installed in the children’s playground. Fred turned up on Friday with a lady whom he and Bob had met during their usual visit to the Take 5 cafe en route to the RSR. Karen Penny is walking around the coast of Britain and Ireland to raise money for Alzeimer’s Research UK and was delighted to be shown around the FRT shed. You can follow Karen’s journey on

Fred turned up on Friday with a lady whom he and Bob had met during their usual visit to the Take 5 cafe en route to the RSR. Karen Penny is walking around the coast of Britain and Ireland to raise money for Alzeimer’s Research UK and was delighted to be shown around the FRT shed. You can follow Karen’s journey on  Fred then continued the task of cleaning FR 20’s boiler ready for painting.

Fred then continued the task of cleaning FR 20’s boiler ready for painting. Bob spent more time working on the new reverser handle for Wootton Hall.

Bob spent more time working on the new reverser handle for Wootton Hall. Members had to resort to a children’s playground table for lunch at the following day’s working party, but we are pleased to be able to report that the man from Preston Locks managed to rectify matters at very reasonable cost in the afternoon and that members will be able to pick up a replacement key for the mess room on their next visit.

Members had to resort to a children’s playground table for lunch at the following day’s working party, but we are pleased to be able to report that the man from Preston Locks managed to rectify matters at very reasonable cost in the afternoon and that members will be able to pick up a replacement key for the mess room on their next visit. Back in the workshop, the overhaul of FR 20 took another step forward with the machining of the tender bearings by Alan Vipond, which had been previously white metalled by Jimmy Dutton.

Back in the workshop, the overhaul of FR 20 took another step forward with the machining of the tender bearings by Alan Vipond, which had been previously white metalled by Jimmy Dutton.  Alan has been busy scraping them in with only one left to do now.

Alan has been busy scraping them in with only one left to do now. Otherwise it has been business as usual with FR 20’s frames undercoated by John, Phil Bell and Roger whilst Fred has been cleaning up FR 20’s boiler for painting.

Otherwise it has been business as usual with FR 20’s frames undercoated by John, Phil Bell and Roger whilst Fred has been cleaning up FR 20’s boiler for painting. Ade can be see here studiously tapping holes on the top of Caliban‘s spring hangers to remove any traces of paint.

Ade can be see here studiously tapping holes on the top of Caliban‘s spring hangers to remove any traces of paint. Alan took the opportunity to explore the ‘J’ pipe on FR 20’s boiler to evaluate whether there was any need to remove it.

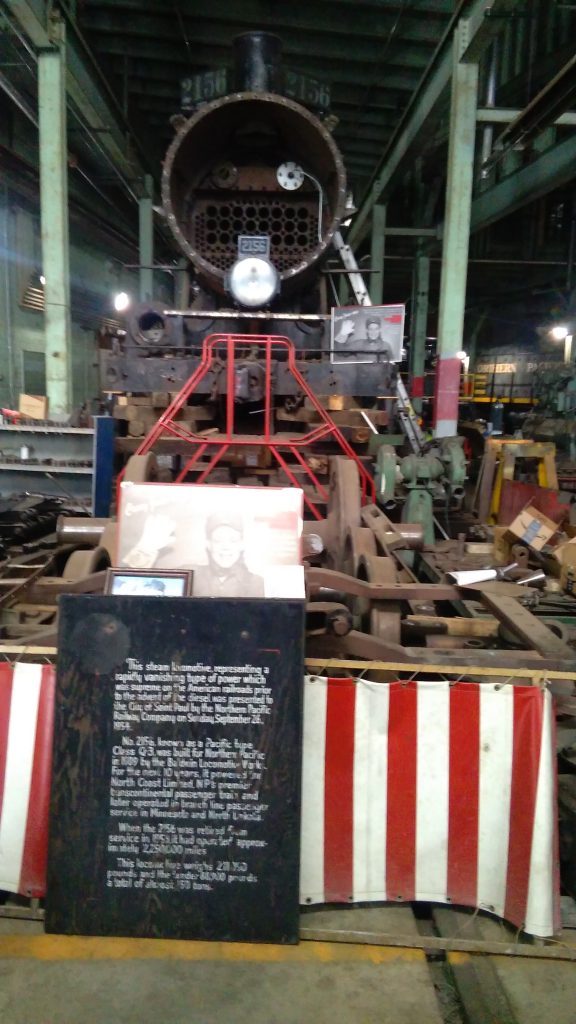

Alan took the opportunity to explore the ‘J’ pipe on FR 20’s boiler to evaluate whether there was any need to remove it. He seems to have found a tender to bring back to Preston for repair (oh no!!) and a Q3 which is being re-built.

He seems to have found a tender to bring back to Preston for repair (oh no!!) and a Q3 which is being re-built.

Work on cleaning and painting FR 20’s frames and motion continued this week. Phil Bell made use of the pit to clean up under the motion.

Work on cleaning and painting FR 20’s frames and motion continued this week. Phil Bell made use of the pit to clean up under the motion. John Dixon, the seemingly headless man, painted under the running board, with Roger continuing the process on Friday.

John Dixon, the seemingly headless man, painted under the running board, with Roger continuing the process on Friday. Tim lined out the tender wheels.

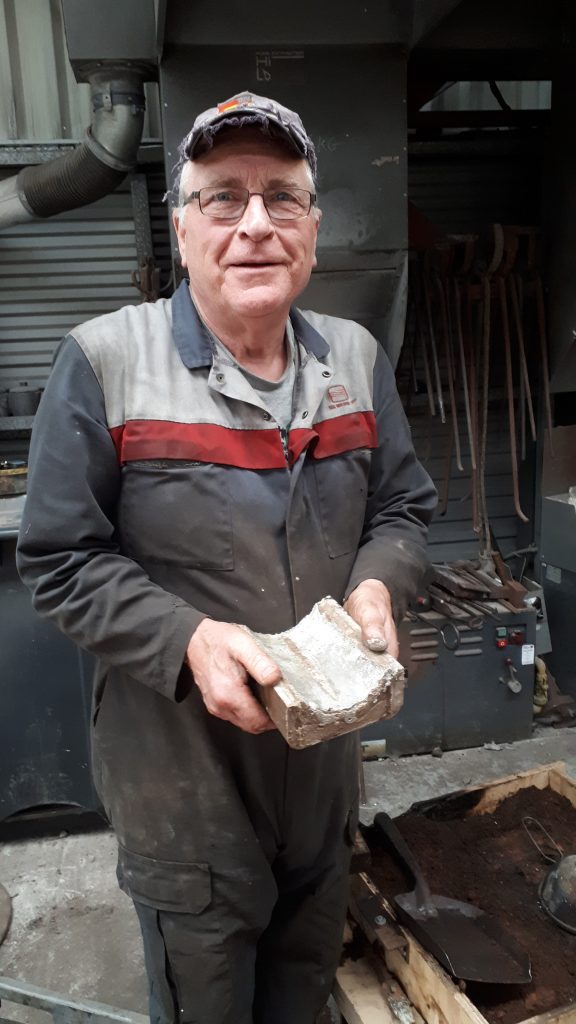

Tim lined out the tender wheels. Jimmy Dutton took on the task of white metalling the tender bearings and is seen here pouring the white metal and with a finished bearing.

Jimmy Dutton took on the task of white metalling the tender bearings and is seen here pouring the white metal and with a finished bearing.

Ade continued to clean and prepare Caliban‘s frames for the next coat of paint.

Ade continued to clean and prepare Caliban‘s frames for the next coat of paint. Outside, Fred and Tim unveiled on the wheelsets the ‘Pacific Blue’ paint shade that will adorn Caliban when completed.

Outside, Fred and Tim unveiled on the wheelsets the ‘Pacific Blue’ paint shade that will adorn Caliban when completed. Finally, some unexpected news this week is that some components have actually been put back on Fluff! John Davis can be seen here with the clutch control mechanism which has been re-fitted after attention.

Finally, some unexpected news this week is that some components have actually been put back on Fluff! John Davis can be seen here with the clutch control mechanism which has been re-fitted after attention. All the pistons have been removed from the liners and given a good soaking in the component wash bath. It is hoped that this process will release the piston rings which, like everything else on Fluff it seems, have seized.

All the pistons have been removed from the liners and given a good soaking in the component wash bath. It is hoped that this process will release the piston rings which, like everything else on Fluff it seems, have seized. Alan is seen here with one of the piston rods.

Alan is seen here with one of the piston rods. Bill Norcross has been machining out recesses in FR 20’s tender axle bearings in order that they can receive white metal.

Bill Norcross has been machining out recesses in FR 20’s tender axle bearings in order that they can receive white metal.

Over to the FRT shed where work has continued on cleaning FR 20’s engine frames, and paint has been applied on Wednesday and Friday by Phil Bell, John Dixon, Roger Benbow and a rare visit on Friday from Neil.

Over to the FRT shed where work has continued on cleaning FR 20’s engine frames, and paint has been applied on Wednesday and Friday by Phil Bell, John Dixon, Roger Benbow and a rare visit on Friday from Neil.

The latter are now turning bright blue with undercoat paint.

The latter are now turning bright blue with undercoat paint. It would be remiss of us not to refer to the step change in train service that took place yesterday on the former Furness Railway. We show a photo of a brand new Class 195 waiting to be ceremonially waved away from Barrow station to Manchester Airport, one of what has doubled to eleven such weekday services that were introduced as part of the timetable change.

It would be remiss of us not to refer to the step change in train service that took place yesterday on the former Furness Railway. We show a photo of a brand new Class 195 waiting to be ceremonially waved away from Barrow station to Manchester Airport, one of what has doubled to eleven such weekday services that were introduced as part of the timetable change. Work has continued at Preston on the overhaul of FR 20 with further preparation for painting. Phil Bell is seen here cleaning the inside of the frames.

Work has continued at Preston on the overhaul of FR 20 with further preparation for painting. Phil Bell is seen here cleaning the inside of the frames. John Dixon (supervised by Ade) has been cleaning the rear running plate around the reverser and also underneath the engine’s drag box and the latter was duly painted with Roger’s help on Friday. Fred and Tim have been cleaning and preparing Caliban‘s wheels for painting.

John Dixon (supervised by Ade) has been cleaning the rear running plate around the reverser and also underneath the engine’s drag box and the latter was duly painted with Roger’s help on Friday. Fred and Tim have been cleaning and preparing Caliban‘s wheels for painting. Various components from Fluff are still receiving attention including the seized clutch control assembly which has been presenting a challenge to Howard.

Various components from Fluff are still receiving attention including the seized clutch control assembly which has been presenting a challenge to Howard. FR 20’s overhaul continues with Alan carrying out work to reduce the ‘clatter’ from the right hand crosshead. He is seen here removing a burr from the piston rod end. John has continued to clean up components and paint them ready for fitting, including the hornstays whilst Phil Bell has been cleaning the frames and reverser quadrant and Tim has applied gloss Indian Red to the wheels.

FR 20’s overhaul continues with Alan carrying out work to reduce the ‘clatter’ from the right hand crosshead. He is seen here removing a burr from the piston rod end. John has continued to clean up components and paint them ready for fitting, including the hornstays whilst Phil Bell has been cleaning the frames and reverser quadrant and Tim has applied gloss Indian Red to the wheels. Jim Hanmer and Alan Preston have made a prompt start to overhauling Fluff‘s engine in the RSR workshop. Jim is seen here with the engine where all the pistons and liners have been removed.

Jim Hanmer and Alan Preston have made a prompt start to overhauling Fluff‘s engine in the RSR workshop. Jim is seen here with the engine where all the pistons and liners have been removed. Extracting the pistons from the liners has proved to be a challenge with something like four tons of force being required to remove the first. The piston rings were found to have seized solid.

Extracting the pistons from the liners has proved to be a challenge with something like four tons of force being required to remove the first. The piston rings were found to have seized solid. The other pistons and liners await their turn.

The other pistons and liners await their turn. Paul Bradshaw and Phil Scales have continued their work on Fluff’s frames.

Paul Bradshaw and Phil Scales have continued their work on Fluff’s frames. Ade has finally found time away from helping others to apply some gloss paint to Caliban’s frames.

Ade has finally found time away from helping others to apply some gloss paint to Caliban’s frames.