Yet another busy week at the workface to report.

Last Tuesday another working party took place at Bury and 5643’s valves were duly delivered by Keith to the FRT shed on Wednesday morning. It is expected that these will be delivered to Tyseley shortly for new rings to be fitted once the re-bore of the valve liners has taken place at the end of the month.

John Dixon has been undertaking final repairs to the roof of GER Royal Saloon No. 5.

John Dixon has been undertaking final repairs to the roof of GER Royal Saloon No. 5.

Down below, Tim has been filling and sanding the old, recently plugged, screw holes in the wooden side canvas retaining strips.

Meanwhile Phil has been busy drilling more screw holes in them!

Meanwhile Phil has been busy drilling more screw holes in them!

John Davis has been cleaning paint off the gas lamp housings.

John Davis has been cleaning paint off the gas lamp housings.

Roger has been cleaning the gas lamp housing rims.

Roger has been cleaning the gas lamp housing rims.

The roof is now totally stripped and a coat of primer is planned over the coming week.

The roof is now totally stripped and a coat of primer is planned over the coming week.

The damp inside Wootton Hall’s tender tank has dissipated now that it is situated inside the heated shed. Keith has been cleaning out the inside of the tank in preparation for welding repairs.

The damp inside Wootton Hall’s tender tank has dissipated now that it is situated inside the heated shed. Keith has been cleaning out the inside of the tank in preparation for welding repairs.

On the outside of the tank. Tim has been cleaning corrosion on the bottom angle of the tank and filling and sanding where necessary.

On the outside of the tank. Tim has been cleaning corrosion on the bottom angle of the tank and filling and sanding where necessary.

Finally, Ade has been assembling the brake gear on Caliban and has found that the brake blocks now need machining to give a good fit following the tyre turning that took place many years ago.

Finally, Ade has been assembling the brake gear on Caliban and has found that the brake blocks now need machining to give a good fit following the tyre turning that took place many years ago.

Back to current activities and we can report that a successful working party was held at Bury last Tuesday to prepare 5643 for the re-bore of its valve liners, which is due to take place at the end of this month.

Back to current activities and we can report that a successful working party was held at Bury last Tuesday to prepare 5643 for the re-bore of its valve liners, which is due to take place at the end of this month. As can be seen, it has been necessary to remove the front buffer beam.

As can be seen, it has been necessary to remove the front buffer beam. John Dixon, Sam Middleton, Keith Brewer and Adrian Tomkinson pose for the camera, which appears to have been ‘photo bombed’ by the gas cylinders.

John Dixon, Sam Middleton, Keith Brewer and Adrian Tomkinson pose for the camera, which appears to have been ‘photo bombed’ by the gas cylinders. Meanwhile John Dixon has uncovered some lincrusta wallpaper on the ceiling of the kitchen compartment in GER No. 5 whilst removing the water tank. It was suggested that this may be an opportunity to reinstate the lincrusta, but it has to be said that John didn’t seem too keen on reviving his lincrusta papering skills that he learned when the North London Railway carriage was restored at Appleby!

Meanwhile John Dixon has uncovered some lincrusta wallpaper on the ceiling of the kitchen compartment in GER No. 5 whilst removing the water tank. It was suggested that this may be an opportunity to reinstate the lincrusta, but it has to be said that John didn’t seem too keen on reviving his lincrusta papering skills that he learned when the North London Railway carriage was restored at Appleby! The tanks was lifted from supporting blocks.

The tanks was lifted from supporting blocks. Then the Ribble Rail lads ensured that the tender chassis was quickly moved underneath.

Then the Ribble Rail lads ensured that the tender chassis was quickly moved underneath. The fitting went every smoothly and the whole job was completed safely in less than 15 minutes. Well done to all.

The fitting went every smoothly and the whole job was completed safely in less than 15 minutes. Well done to all. Once back inside the shed Keith was busy fitting temporary bolts to hold down the tank.

Once back inside the shed Keith was busy fitting temporary bolts to hold down the tank. There has been good progress with GER Royal Saloon GER No. 5. Neil and Caitlin came in on the 31st December, Neil to clean the inside of the coach of debris deposited when items were removed from the roof, and Caitlin to strip paint from roof rain strips.

There has been good progress with GER Royal Saloon GER No. 5. Neil and Caitlin came in on the 31st December, Neil to clean the inside of the coach of debris deposited when items were removed from the roof, and Caitlin to strip paint from roof rain strips. Removing paint from the wooden side retaining strips has also devoured a great deal of time with Phil Burton seen here setting up a planing machine to clean the straight edges.

Removing paint from the wooden side retaining strips has also devoured a great deal of time with Phil Burton seen here setting up a planing machine to clean the straight edges. Meanwhile John Davis used a heat gun on the process.

Meanwhile John Davis used a heat gun on the process. The gas lamp housings are being cleaned up by Ed and the corrosion revealed now needs some attention as can be seen here.

The gas lamp housings are being cleaned up by Ed and the corrosion revealed now needs some attention as can be seen here. Phil Bell has been employed making plugs to fill old screw holes in the retaining strips. Meanwhile Tim has completed the sanding of the roof boards.

Phil Bell has been employed making plugs to fill old screw holes in the retaining strips. Meanwhile Tim has completed the sanding of the roof boards. Now that Caliban has been lowered on to its wheels, Ade has been undertaking some early spring cleaning.

Now that Caliban has been lowered on to its wheels, Ade has been undertaking some early spring cleaning. Alan has been emptying his garage and has located some of Caliban’s brass items which Sam brought in for cleaning and storage. Alan and Sam have also been taking measurements of Caliban’s smokebox in order that a quote for a replacement can be obtained.

Alan has been emptying his garage and has located some of Caliban’s brass items which Sam brought in for cleaning and storage. Alan and Sam have also been taking measurements of Caliban’s smokebox in order that a quote for a replacement can be obtained. Christmas may well be nearly upon us but that hasn’t stopped work in the FRT shed. The major happening last Wednesday was a pre-Christmas shunt of the shed which moved Wootton Hall’s tender chassis to the front of the heated section of the shed. It can be seen here making its first appearance in daylight since being re-wheeled earlier in the year. There is a plan to fit the tender tank on top of the chassis on Wednesday, 5th January, hence the need to move it nearer to the shed entrance.

Christmas may well be nearly upon us but that hasn’t stopped work in the FRT shed. The major happening last Wednesday was a pre-Christmas shunt of the shed which moved Wootton Hall’s tender chassis to the front of the heated section of the shed. It can be seen here making its first appearance in daylight since being re-wheeled earlier in the year. There is a plan to fit the tender tank on top of the chassis on Wednesday, 5th January, hence the need to move it nearer to the shed entrance. Keith has continued to work on Wootton Hall‘s boiler cladding, making up some of the more difficult (origami?!) pieces around the front of the firebox which bend in various planes.

Keith has continued to work on Wootton Hall‘s boiler cladding, making up some of the more difficult (origami?!) pieces around the front of the firebox which bend in various planes. The last of the bonding compound that held the previous canvas in place has now been removed from the roof of GER Royal Saloon No. 5, and the aforementioned shunt allowed the hydraulic platform to be positioned at the west end of the vehicle to allow the end pieces of wood that hold the canvas in place to be removed.

The last of the bonding compound that held the previous canvas in place has now been removed from the roof of GER Royal Saloon No. 5, and the aforementioned shunt allowed the hydraulic platform to be positioned at the west end of the vehicle to allow the end pieces of wood that hold the canvas in place to be removed. Phil Burton has been removing old paint from the roof rain strips from GER No. 5.

Phil Burton has been removing old paint from the roof rain strips from GER No. 5. Fred, having previously cleaned the paint off the torpedo vents, has commenced the task of adding new paint.

Fred, having previously cleaned the paint off the torpedo vents, has commenced the task of adding new paint. John Davis continued his quest to paint every nook and cranny in Fluff‘s cab.

John Davis continued his quest to paint every nook and cranny in Fluff‘s cab. Roger spent Friday giving the fire pump a 300 gallon service and clean, in readiness for its next use.

Roger spent Friday giving the fire pump a 300 gallon service and clean, in readiness for its next use. A milestone in the overhaul of Caliban was reached on Wednesday when Ade, with assistance from Alan, finally lowered the chassis back onto its wheels.

A milestone in the overhaul of Caliban was reached on Wednesday when Ade, with assistance from Alan, finally lowered the chassis back onto its wheels.  Just for the record, the operation went very smoothly with no problems in lining up the axleboxes – for once! Well done!

Just for the record, the operation went very smoothly with no problems in lining up the axleboxes – for once! Well done! Some of Fluff‘s cab controls have been cleaned up and have been laid out ready for painting.

Some of Fluff‘s cab controls have been cleaned up and have been laid out ready for painting. Work on Wootton Hall has continued with Keith seen here tapping a hole in the cladding, most of which has now been fitted.

Work on Wootton Hall has continued with Keith seen here tapping a hole in the cladding, most of which has now been fitted.  There remain the tricky items to fabricate and fit around the front corners of the firebox.

There remain the tricky items to fabricate and fit around the front corners of the firebox. There was a real push this last week to clear the roof of GER Royal Saloon No. 5 from the bonding compound that had held down the previous canvas. It has been a long job with around 500 square feet of wood to clean, heat guns and scrapers being the most efficient method.

There was a real push this last week to clear the roof of GER Royal Saloon No. 5 from the bonding compound that had held down the previous canvas. It has been a long job with around 500 square feet of wood to clean, heat guns and scrapers being the most efficient method.  Phil Burton (seen here), Ed, Paul Balshaw, John Dixon and Tim have all spent time on the job this week and we are now on the last lap. It will then be necessary to sand down the wood and apply a coat of primer before tackling the job of fitting the new canvas.

Phil Burton (seen here), Ed, Paul Balshaw, John Dixon and Tim have all spent time on the job this week and we are now on the last lap. It will then be necessary to sand down the wood and apply a coat of primer before tackling the job of fitting the new canvas. Ade has managed to spend some more time on Caliban when not shunting Christmas coaches for the RSR. He is seen here lowering Caliban‘s frames closer towards the axleboxes.

Ade has managed to spend some more time on Caliban when not shunting Christmas coaches for the RSR. He is seen here lowering Caliban‘s frames closer towards the axleboxes. Phil Bell and John Davis have still been finding work to do on Fluff with Phil reaming out a hole for one of the taper pins that holds the right hand coupling rod in position.

Phil Bell and John Davis have still been finding work to do on Fluff with Phil reaming out a hole for one of the taper pins that holds the right hand coupling rod in position. Keith is still working on the boiler cladding for Wootton Hall and has been riveting the end cleats to the boiler bands.

Keith is still working on the boiler cladding for Wootton Hall and has been riveting the end cleats to the boiler bands. The new cage for the gas bottles has not been forgotten and John Dixon has been progressing with this project when not working on GER No. 5’s roof.

The new cage for the gas bottles has not been forgotten and John Dixon has been progressing with this project when not working on GER No. 5’s roof. Finally, whether we like it or not, the festive period has most definitely arrived with Keith and Ade driving the RSR’s Santa trains over the weekend. Given the current Covid situation, it was agreed that Alan and Tim would this year play Christmas songs and carols at the entrance to the museum rather than on the trains. Alan is seen here using a kazoo to add to the sound, with err a mixed reception!?!

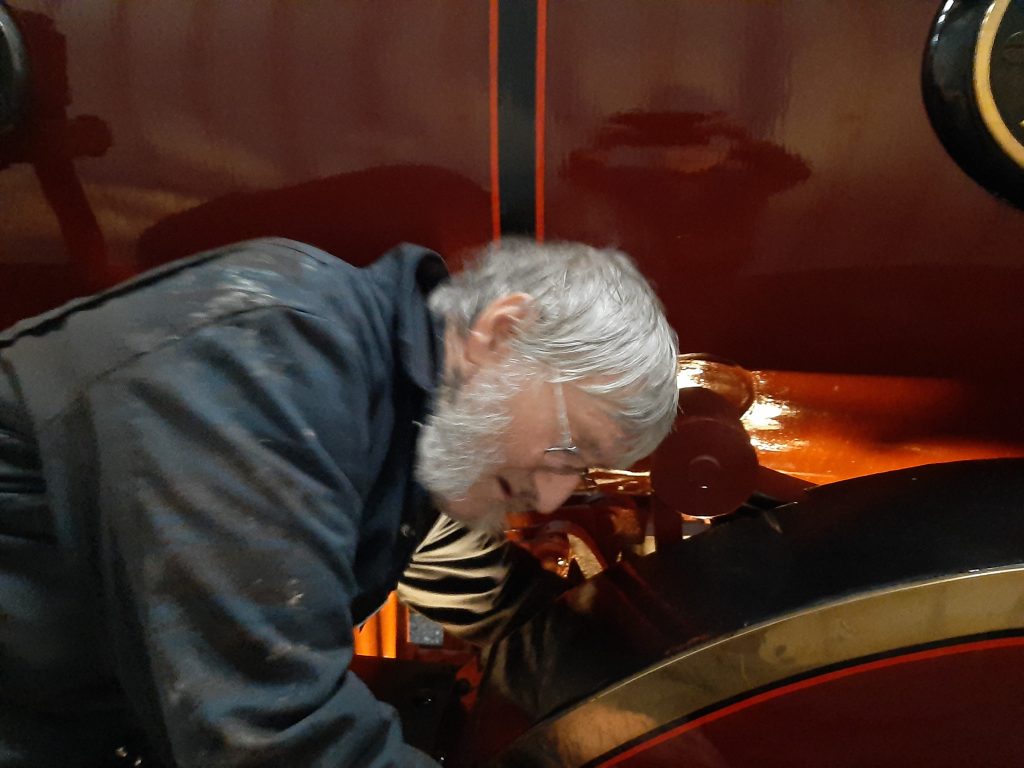

Finally, whether we like it or not, the festive period has most definitely arrived with Keith and Ade driving the RSR’s Santa trains over the weekend. Given the current Covid situation, it was agreed that Alan and Tim would this year play Christmas songs and carols at the entrance to the museum rather than on the trains. Alan is seen here using a kazoo to add to the sound, with err a mixed reception!?! The main news is that a washout of FR 20’s boiler was successfully carried out last Wednesday, the first to be undertaken using the Coventry Climax fire pump that was purchased just before the first lock down. Former members Jon Dixon and Neil Glover, who are used to dealing with fire pumps, came to give us a hand and, after setting everything up carefully, everything worked and went to plan! (How did that happen, you may ask?!!) The photo shows Jon aiming the water into a plug hole in FR 20’s front tubeplate whilst Neil controls the fire pump and Alan inspects the colour of the water running out of the firebox plug holes. The purpose of using the fire pump is that it can deliver water into the boiler at a far greater pressure than from the mains and so be more efficient in removing sludge and scale. The big question that needed answering was whether the pump would be able to lift the feed water from the tender tank through the suction hoses; the answer was a very positive yes. We are grateful to Jon and Neil for their assistance and hope that Jon managed to clean himself up after managing to get himself covered in a mixture of soot and water!

The main news is that a washout of FR 20’s boiler was successfully carried out last Wednesday, the first to be undertaken using the Coventry Climax fire pump that was purchased just before the first lock down. Former members Jon Dixon and Neil Glover, who are used to dealing with fire pumps, came to give us a hand and, after setting everything up carefully, everything worked and went to plan! (How did that happen, you may ask?!!) The photo shows Jon aiming the water into a plug hole in FR 20’s front tubeplate whilst Neil controls the fire pump and Alan inspects the colour of the water running out of the firebox plug holes. The purpose of using the fire pump is that it can deliver water into the boiler at a far greater pressure than from the mains and so be more efficient in removing sludge and scale. The big question that needed answering was whether the pump would be able to lift the feed water from the tender tank through the suction hoses; the answer was a very positive yes. We are grateful to Jon and Neil for their assistance and hope that Jon managed to clean himself up after managing to get himself covered in a mixture of soot and water!

Phil Bell and John Davis made further progress with Fluff by re-fitting the rods, which went back on with little bother once the wheels had been lined up. We still await the new cab roof and there are no doubt many other jobs to complete.

Phil Bell and John Davis made further progress with Fluff by re-fitting the rods, which went back on with little bother once the wheels had been lined up. We still await the new cab roof and there are no doubt many other jobs to complete. Should John and Phil ever run out of work, we can surely point them towards the roof of GER No.5 where, having removed the lamp housings, vents, conduit and canvas, there is now the tedious task of removing the canvas bonding compound, some of which is resolutely stuck fast to the wooden roof planks. Ed and John Dixon have made a start but it seems that heat guns are the solution to the problem.

Should John and Phil ever run out of work, we can surely point them towards the roof of GER No.5 where, having removed the lamp housings, vents, conduit and canvas, there is now the tedious task of removing the canvas bonding compound, some of which is resolutely stuck fast to the wooden roof planks. Ed and John Dixon have made a start but it seems that heat guns are the solution to the problem. With the fire pump now in operational order, we are now looking towards what we need to do to use it to conduct a high pressure boiler wash out. In advance of a gathering this next Wednesday to progress the project, Alan has come up with a modified hose branch which should manage to aim the water to all the required nooks and crannies on FR 20’s boiler. With the right hand piston rod cotter adjustments now completed we will be able to move the loco outside the shed with the first job being to drop the existing water in the boiler.

With the fire pump now in operational order, we are now looking towards what we need to do to use it to conduct a high pressure boiler wash out. In advance of a gathering this next Wednesday to progress the project, Alan has come up with a modified hose branch which should manage to aim the water to all the required nooks and crannies on FR 20’s boiler. With the right hand piston rod cotter adjustments now completed we will be able to move the loco outside the shed with the first job being to drop the existing water in the boiler. At 14.45 on Friday, the peace of the FRT shed was shattered without warning by the earthy roar of a Coventry Climax engine, announcing to all that the three days of work that Roger had expended on the fire pump had been successful. Well done, Roger! We now need to see how the machine copes with washing out a locomotive boiler!

At 14.45 on Friday, the peace of the FRT shed was shattered without warning by the earthy roar of a Coventry Climax engine, announcing to all that the three days of work that Roger had expended on the fire pump had been successful. Well done, Roger! We now need to see how the machine copes with washing out a locomotive boiler! There has been further progress on clearing the roof of GER Royal Saloon No. 5 with Ed and John seen here working in tandem on the magic carpet to remove the remaining rain strips and canvas.

There has been further progress on clearing the roof of GER Royal Saloon No. 5 with Ed and John seen here working in tandem on the magic carpet to remove the remaining rain strips and canvas. Fred has once again been cleaning up the torpedo vents – usually two in a day. Yet more cup wire brushes to order!

Fred has once again been cleaning up the torpedo vents – usually two in a day. Yet more cup wire brushes to order! Anne and Phil Burton have been making steady progress on the upholstery in GER No. 5. They have obtained some cheaper moquette with which to practice on re-covering the cushions.

Anne and Phil Burton have been making steady progress on the upholstery in GER No. 5. They have obtained some cheaper moquette with which to practice on re-covering the cushions. The finished article looks pretty good. They aim to have one more practice cushion before the selected, rather more expensive, moquette is purchased, which we feel will be more appropriate for a royal saloon.

The finished article looks pretty good. They aim to have one more practice cushion before the selected, rather more expensive, moquette is purchased, which we feel will be more appropriate for a royal saloon. More progress has been made with fitting the cladding on 4979 Wootton Hall’s boiler. It is a team job to get the sheets on top of the boiler as can be seen here.

More progress has been made with fitting the cladding on 4979 Wootton Hall’s boiler. It is a team job to get the sheets on top of the boiler as can be seen here. The third sheet on the right hand side has now been fitted.

The third sheet on the right hand side has now been fitted. Meanwhile, Tim has been devoting his time recently to tidying up 4979’s fabricated cab side stanchions with filler so that they look more like Swindon manufactured pressings. The cab sides are also starting to receive attention where they have suffered after having been exposed to 50 years of the elements.

Meanwhile, Tim has been devoting his time recently to tidying up 4979’s fabricated cab side stanchions with filler so that they look more like Swindon manufactured pressings. The cab sides are also starting to receive attention where they have suffered after having been exposed to 50 years of the elements. Elsewhere, Ade has, amongst other things, been fitting brake blocks to Caliban’s chassis. Alan and Sam have been adjusting the miscreant piston rod cotter on FR 20. Incidentally, there is now video footage available from a cab mounted camera of FR 20’s first trip in service on the RSR after overhaul:

Elsewhere, Ade has, amongst other things, been fitting brake blocks to Caliban’s chassis. Alan and Sam have been adjusting the miscreant piston rod cotter on FR 20. Incidentally, there is now video footage available from a cab mounted camera of FR 20’s first trip in service on the RSR after overhaul: We are pleased to report further progress with Wootton Hall with the wooden packing on the tender frames dovetailed together and all but complete. Once finished it will then be possible to plan lifting the tender tank on to the frames where it can be more easily repaired inside the shed.

We are pleased to report further progress with Wootton Hall with the wooden packing on the tender frames dovetailed together and all but complete. Once finished it will then be possible to plan lifting the tender tank on to the frames where it can be more easily repaired inside the shed. The opportunity was taken last Wednesday to test the tender brake cylinder which has been refurbished. The cylinder was taken around to the Ribble Steam Railway running shed where it was connected up to vacuum braked diesel shunter Stanlow. Keith and Duncan Sawyer are seen ensuring the connections are correct.

The opportunity was taken last Wednesday to test the tender brake cylinder which has been refurbished. The cylinder was taken around to the Ribble Steam Railway running shed where it was connected up to vacuum braked diesel shunter Stanlow. Keith and Duncan Sawyer are seen ensuring the connections are correct. The pipework involved is seen here and it appears that the test was successful.

The pipework involved is seen here and it appears that the test was successful. Last Wednesday also saw our folk group, Live Steam, performing on platform 3 at Lancaster station as part of the finale to the Furness Railway 175 celebrations. The lads are seen here sitting down for their lengthy second set of railway songs.

Last Wednesday also saw our folk group, Live Steam, performing on platform 3 at Lancaster station as part of the finale to the Furness Railway 175 celebrations. The lads are seen here sitting down for their lengthy second set of railway songs.